Cold-formed structures

Cold-formed structures represent a rapidly evolving sector within the construction industry, offering the freedom to develop innovative cross-sections. However, understanding the true behavior of such structures, like local and distortional buckling, proves exceedingly complex, requiring sophisticated analysis and design tools.

No credit card required

Cold-formed steel specific feature solutions in Consteel

Parametric cold-formed profiles

Extended possibilities are provided for our users to define the most commonly used types of cold-formed sections parametrically. Z, C, Sigma, Zeta, hat, L and closed profiles are all available with possible web, flange and edge stiffeners where applicable. Definition is straightforward and design is handled through General Method in a fully Eurocode-conform way with the consideration of supplementary rules of EN 1993-1-3.

Adaptive eccentricity of loads and supports

Loads and supports are placed on the members’ reference line by default which corresponds to the gravity center of the cross-section. Defining eccentricities is also possible. Eccentricities are always relative to the cross-section’s dedicated points and so the placement of the load or the support adopt to the changes of the section.

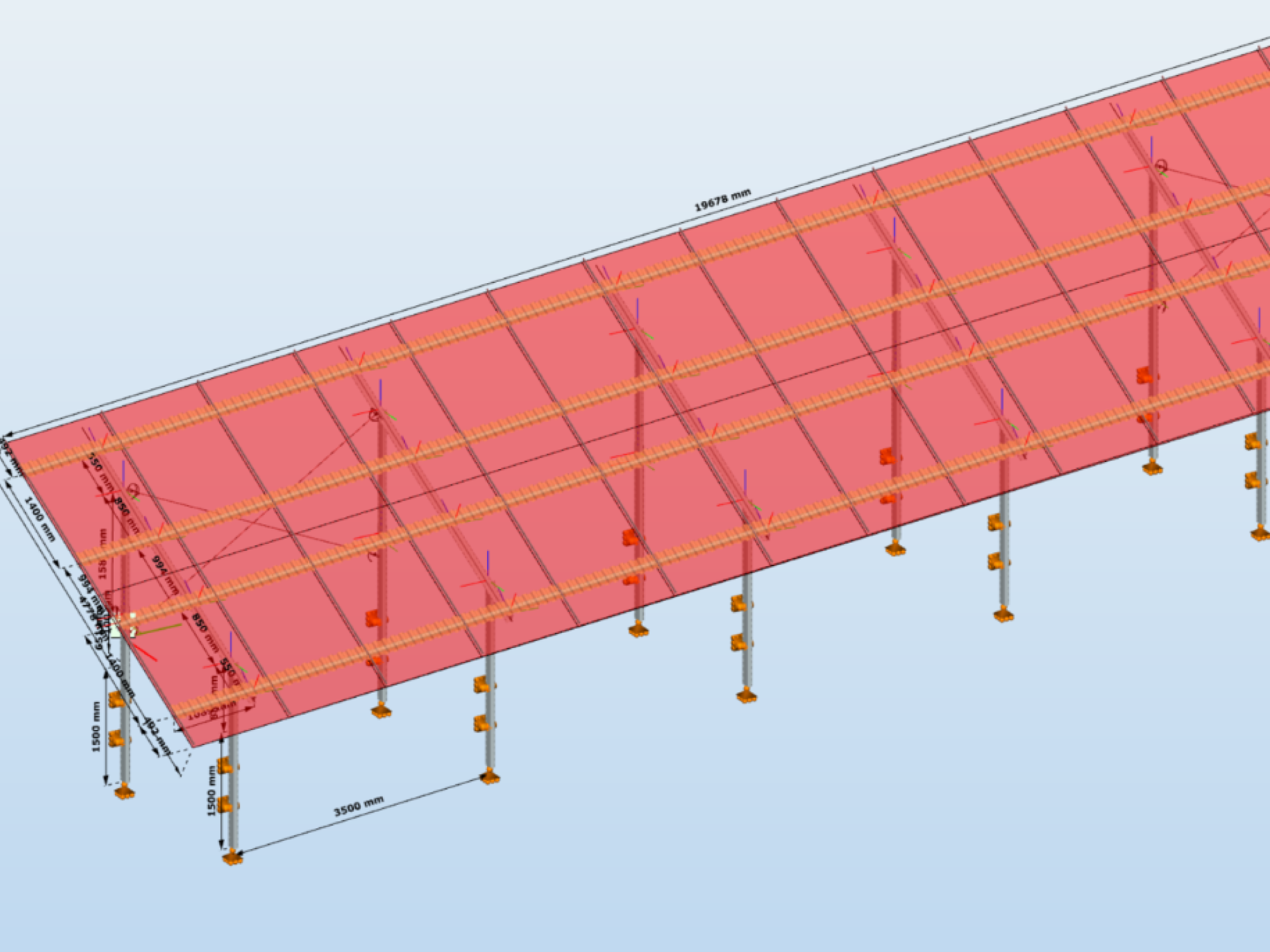

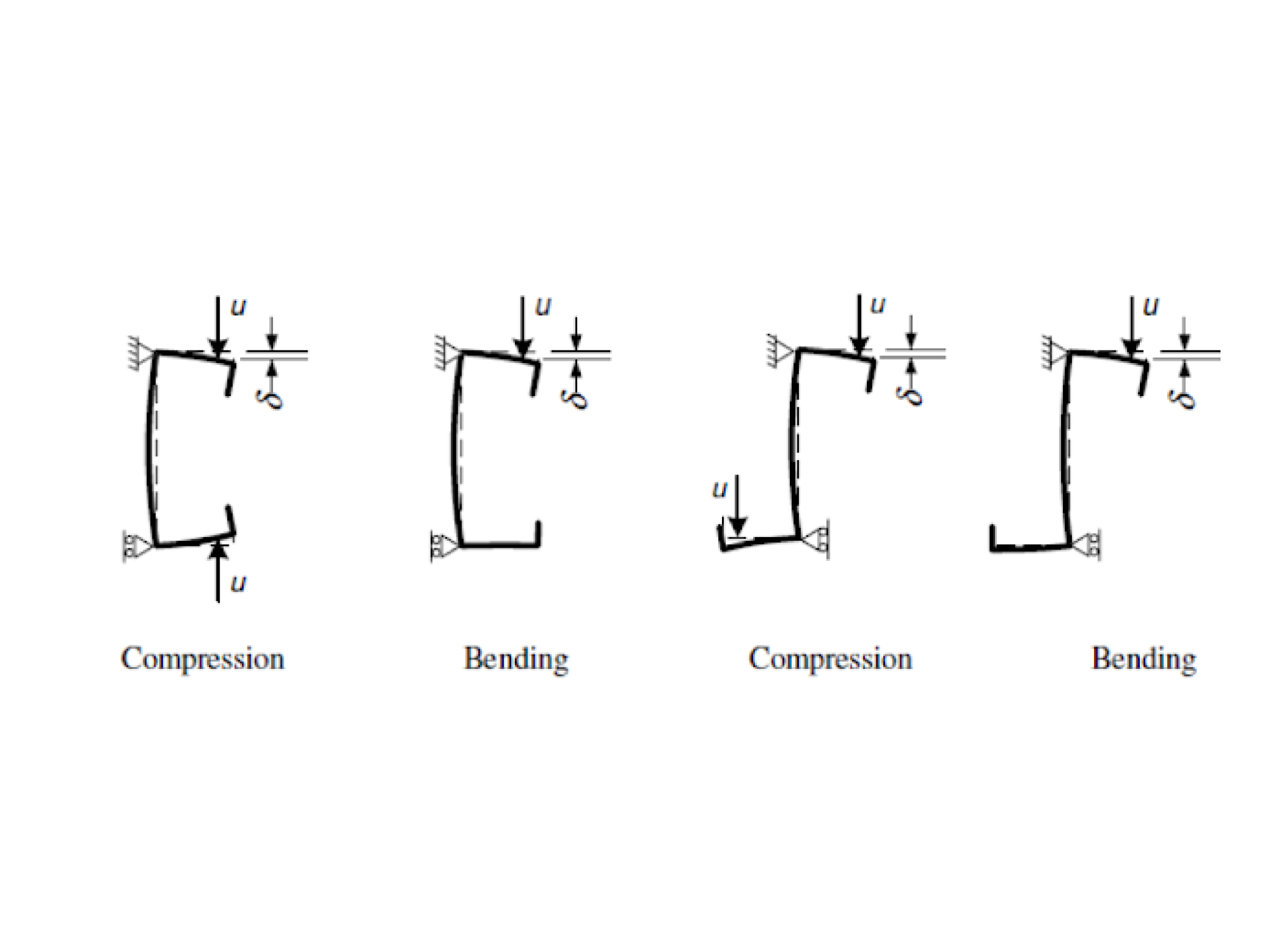

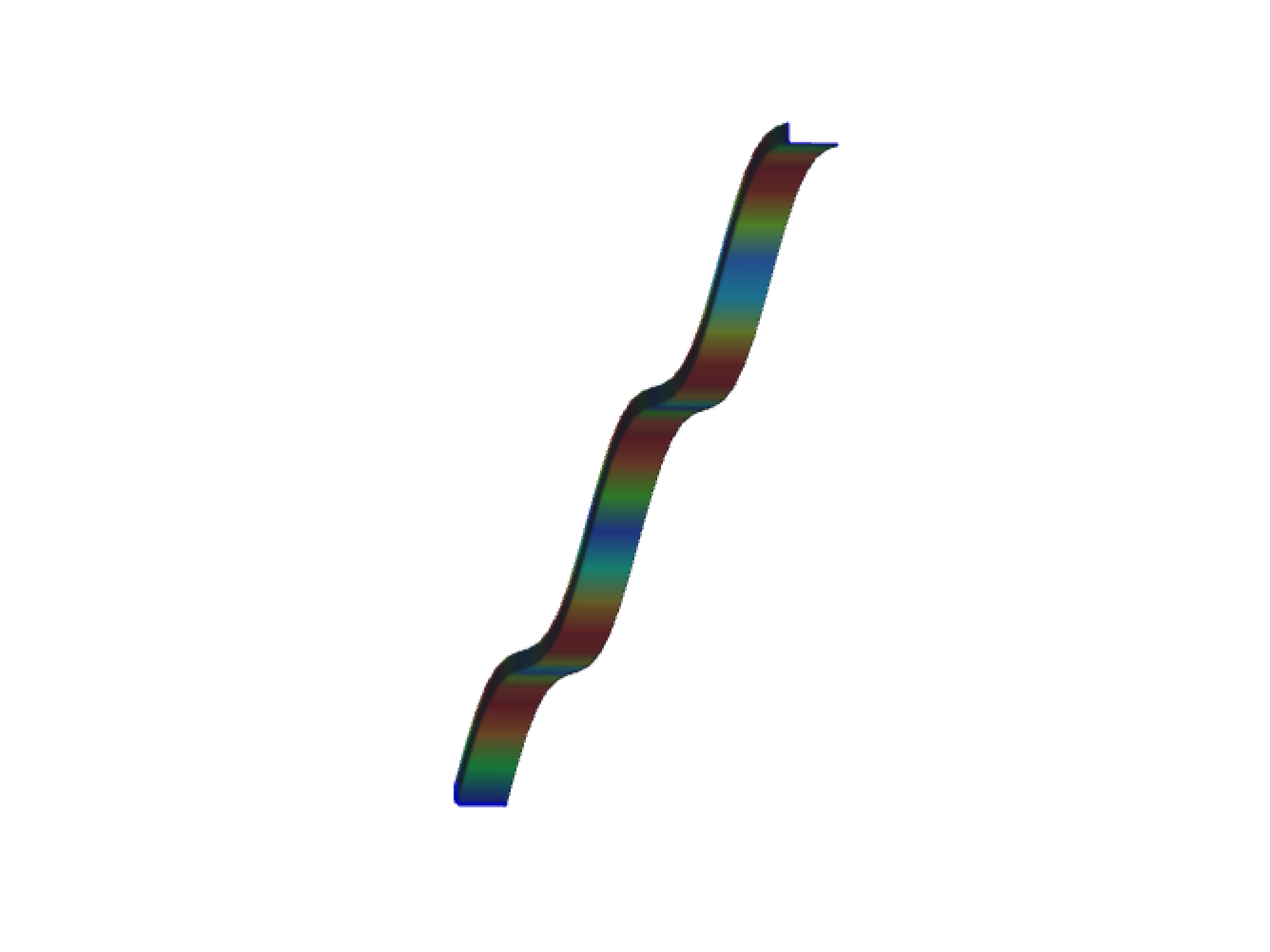

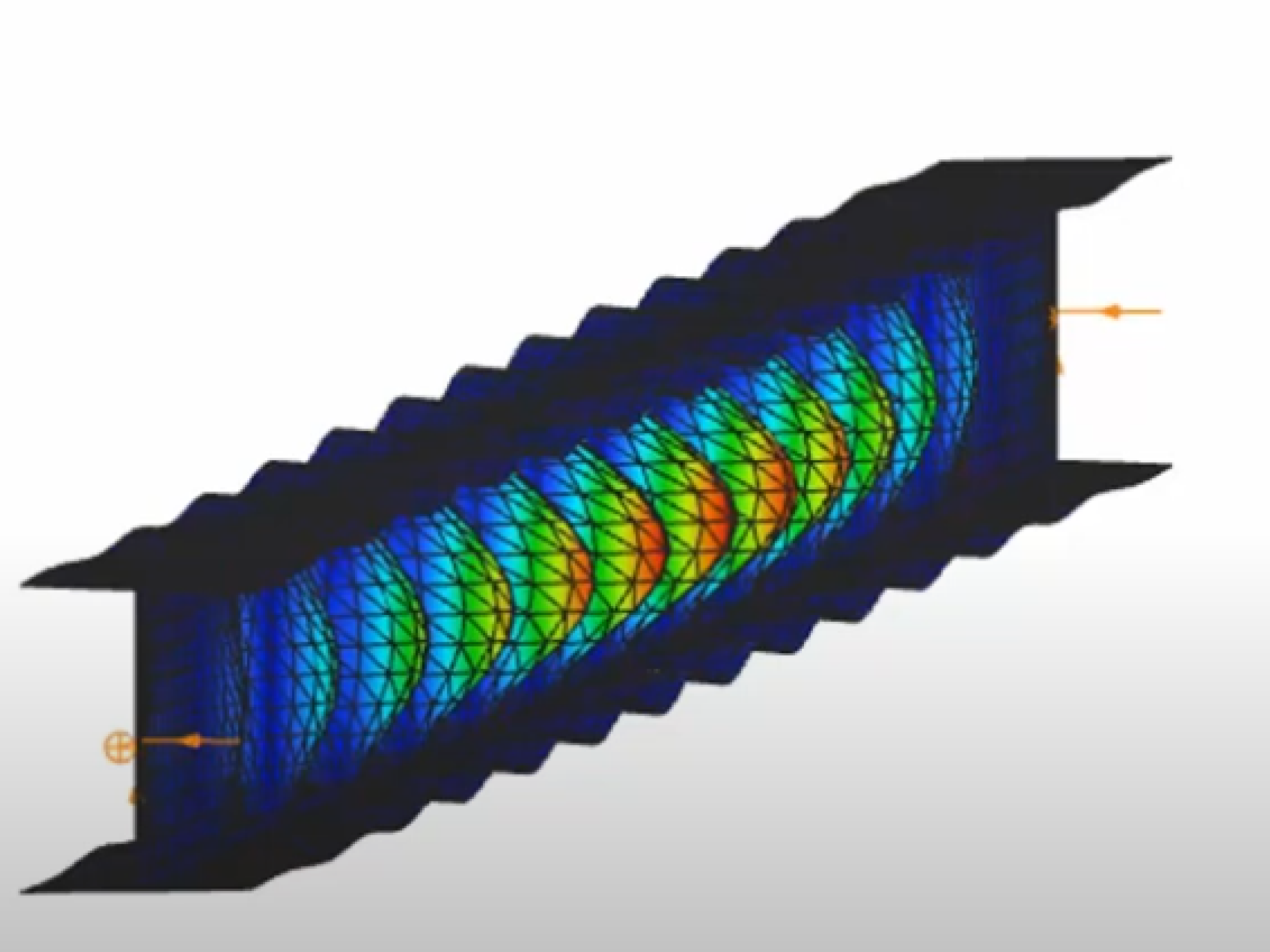

Local and distortional buckling design of parametric cold-formed profiles

In Consteel, numerous different cold-formed sections can be defined parametrically, including Z, C, U, Sigma, Zeta and hat sections with variations of edge, flange and web stiffeners. Complete design calculation is provided for all of them considering local buckling according to EN 1993-1-5 and distortional buckling as per EN 1993-1-3 and interaction of those, fully automatically.

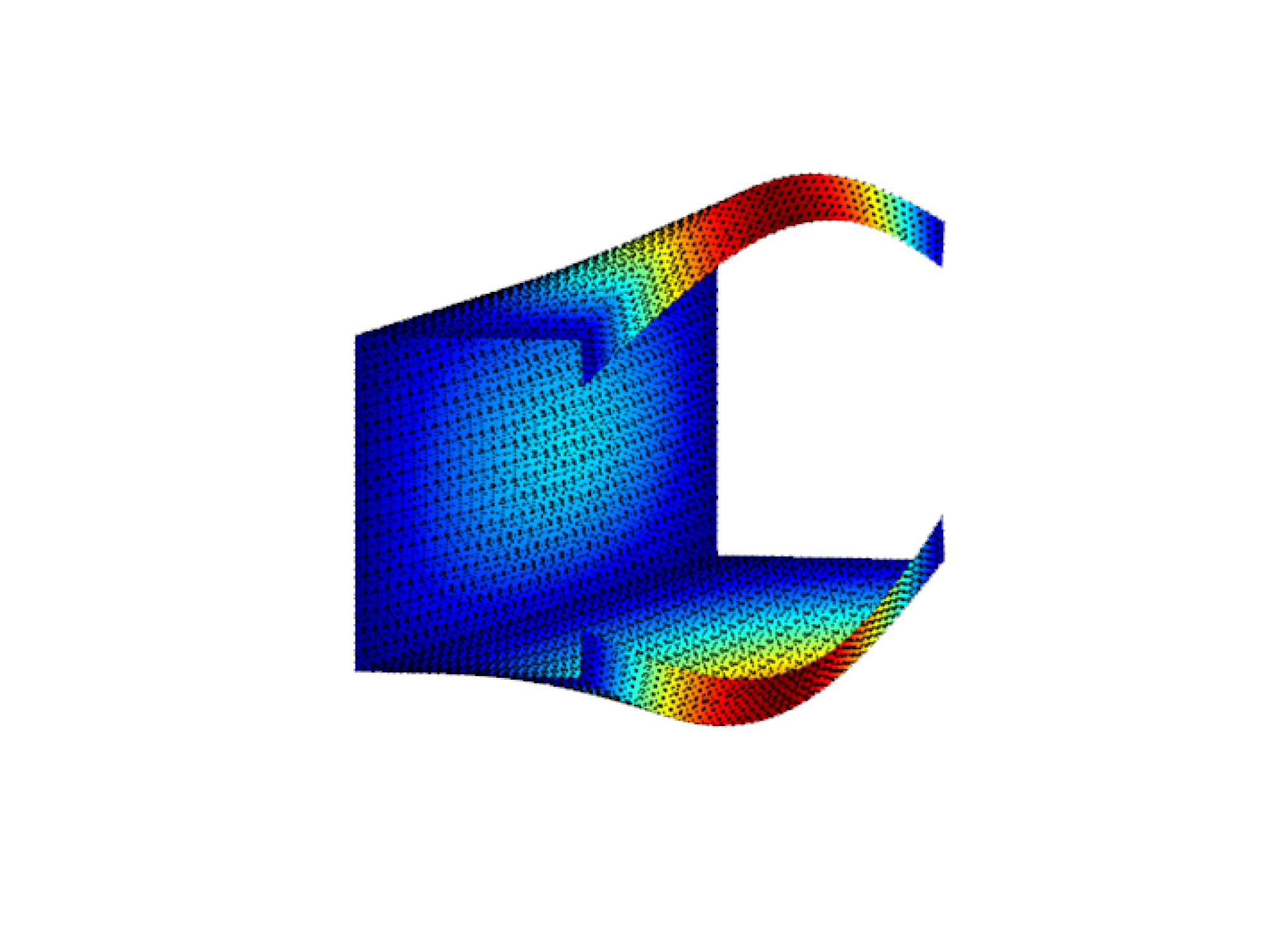

Easy modeling of purlins – Purlinline

Considering shear and rotational restraints provided by the various types of sheeting is unavoidable during cold-formed purlin design. In Consteel, the definition of these restraints is practical for everyday use and supplemented with an automatically applied special purlin design mode of analysis and design calculations. As purlins can be modelled as integrated parts of the structural model, their restraining effect to the main structure can also be considered.

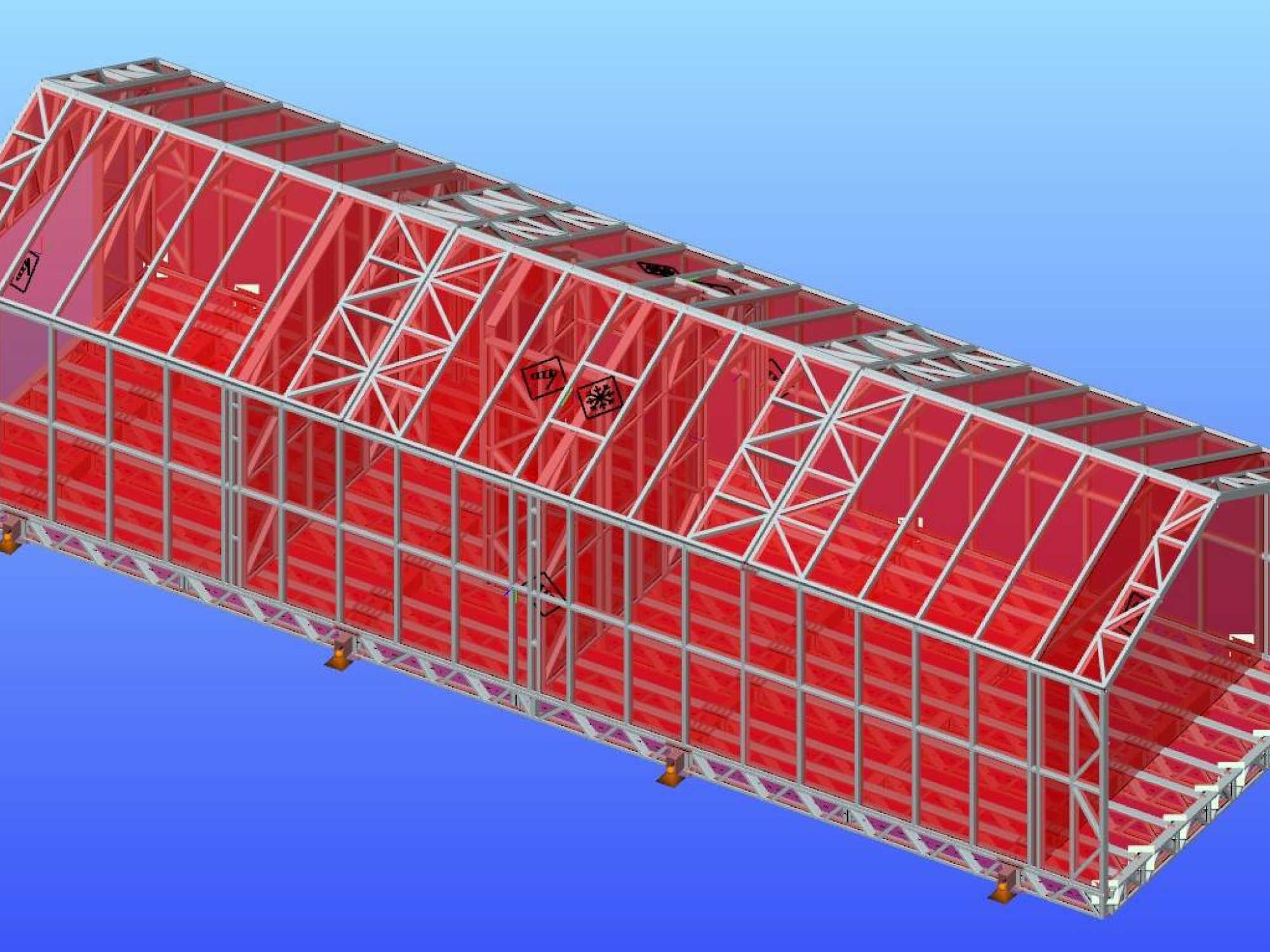

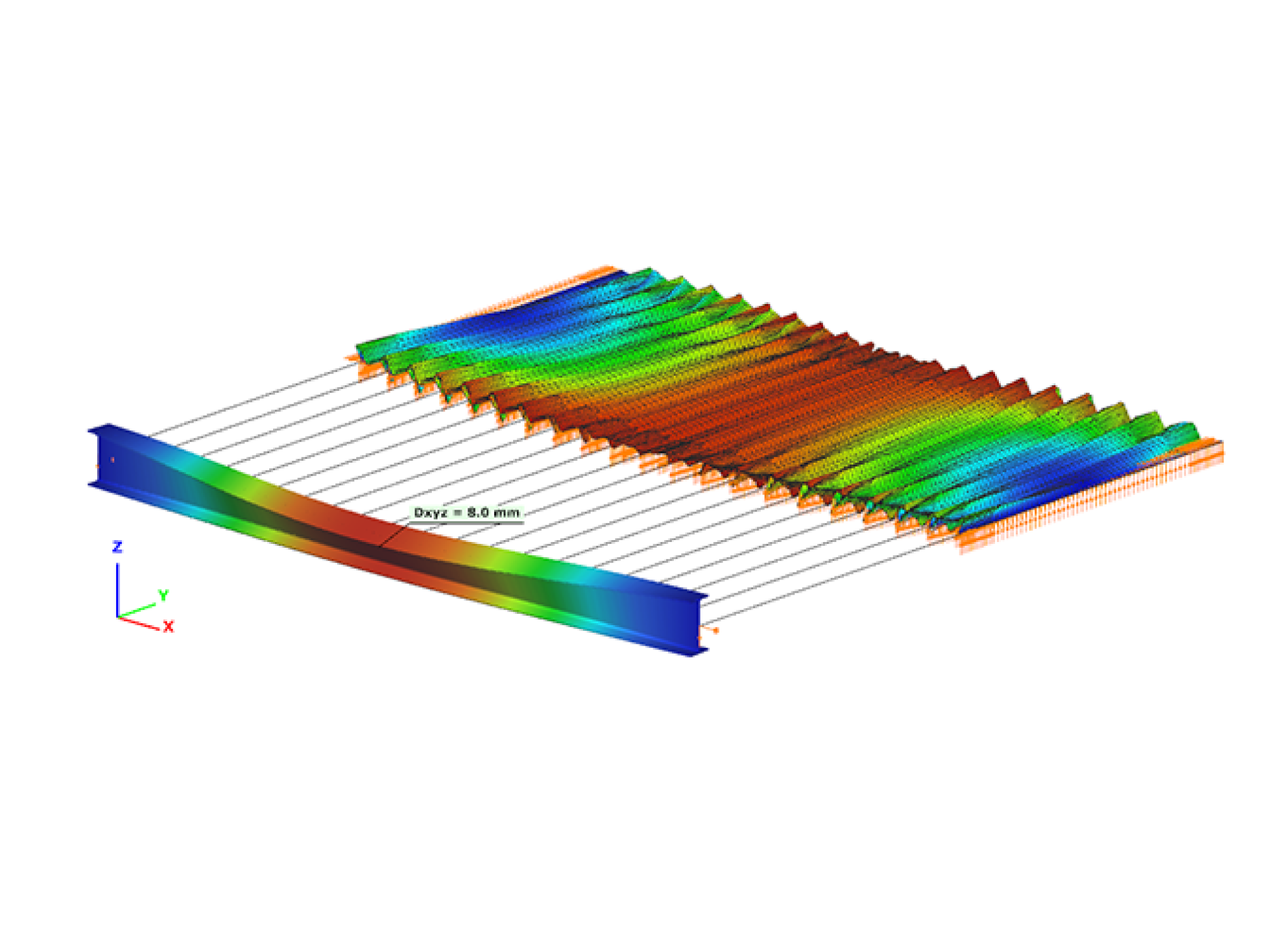

Easy modeling of the effect of sheeting – Shear field

Considering the shear restraint of trapezoidal steel decking is always a question. Can the floor beams be considered as fully restrained or not? In Consteel, various types of trapezoidal sheetings are available and the actual shear stiffness of the application can be calculated either by the Eurocode or with methods provided by producers. Consequently, the actual shear restraints can be applied in the analysis and automatic design of the beams.

How can consteel enhance your work?

OUR PARTNERS

ReferenceS by OUR users

WHY CHOOSE CONSTEEL?

WHO RECOMMENDS US?

‘Consteel is a great asset for Arambol Ingeniería S.L. Thanks to its workflow we can design, calculate and present a project in record time. The program is very intuitive and easy to use. Technically, the seventh degree of freedom is an enormously useful tool to check structures with the general method, and even obtain reliable results thanks to the use of buckling shapes together with the imperfections to obtain utilization ratios that, physically, are more realistic than the reduction coefficients. Consteel has very specialized features such as the shear field or the frame corner wizard that add an extra degree of professionalism to the calculation, which translates into greater efficiency in the use of steel and, therefore, money.’

‘The Alba Arena project highlighted the extraordinary potential of the Consteel software and Pangolin. It is a pioneering technology that enables the parametric design of complex geometry and large-scale structures through the Grasshopper system. The Pangolin award is an exceptional recognition for me and the bim.GROUP, as it is a positive feedback on the quality of our work and an opportunity to showcase our expertise on an international level.’ said Dávid Lewandowski, Steel Structure Designer, regarding the award.’

‘Consteel’s technical support team is very professional. Especially Mr. Balint Vaszilievits-Sömjén, he has been a great help to us! We were impressed by his professionalism and dedication. We are satisfied with the use of Consteel, which has proven its worth in our international projects.’

‘I started using the Consteel design software during my university studies, when it was Consteel version 6. Even then I was impressed by the simplicity, transparency, and speed of the program. Since then, I have had the pleasure of designing many structures with the program, from small to large: industrial halls, office buildings, large opening roof structures, staircases, flying garages, pipe bridges, canopies, secondary closure elements, or the transmission line poles on which my doctoral thesis was based.

The bottom line is that it allows a structural engineer to model any structure in 3D in a structurally correct way, yet quickly and with a low risk of error. The most complex geometric type includes, for example, a lattice structure, where stability loss shapes can be efficiently calculated and sections optimised. One of my favourite features is the interpretability of the results, and the fact that the program receives significant updates year after year, which is the most user-oriented.’

‘From the very beginning, I really like Consteel because it can be used to perform global steel structure tests in a complex and compact way, efficiently. In addition, the software integrates well with automated parameter-driven design algorithms – so I can heartily recommend it.’

The approach of the Consteel team to software development also deserves praise, which shows a well-thought-out path of software development in terms of suitability for practical applications (and not only in terms of changing the graphic interface as is the case in other developers).

We recommend Consteel to all experienced engineers.’

knowledge behind consteel

Example ModelS

Perform buckling checks for cold-formed members

Did you know that you could use Consteel to perform local and distortional buckling checks for cold-formed members?

Download the example model and try it!

SIMPLIFY YOUR DESIGN PROCESS