Modeling stiffeners in Consteel

With Superbeam feature in Consteel, modelling of stiffeners is easy and effective. Multiple options and various shapes are available. Analysis is possible with beam and shell elements either.

gateTheoretical background

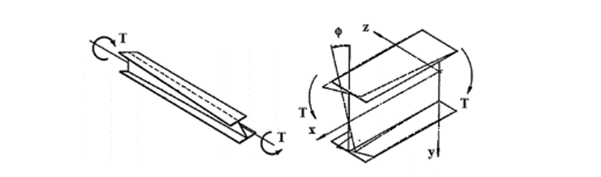

According to the beam-column theory, two types of torsional effects exist.

Saint-Venant torsional component

Some closed thin-walled cross-sections produce only uniform St. Venant torsion if subjected to torsion. For these, only shear stress τt occurs.

The non-uniform torsional component

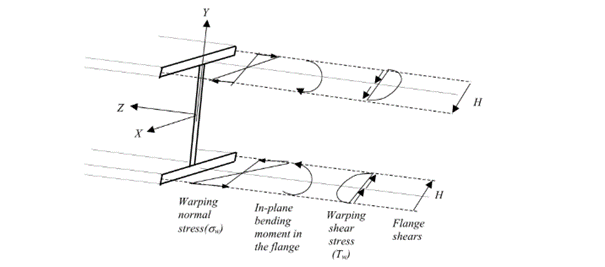

Open cross-sections might produce also normal stresses as a result of torsion.[1.]

Warping causes in-plane bending moments in the flanges. From the bending moment arise both shear and normal stresses as it can be seen in Fig. 2 above.

Discrete warping restraint

The load-bearing capacity of a thin-walled open section against lateral-torsional buckling can be increased by improving the section’s warping stiffness. This can be done by adding additional stiffeners to the section at the right locations, which will reduce the relative rotation between the flanges due to the torsional stiffness of this stiffener. In Consteel, such stiffener can be added to a Superbeam using the special Stiffener tool. Consteel will automatically create a warping support in the position of the stiffener, the stiffness of which is calculated using the formulas below. Of course, warping support can also be defined manually by specifying the correct stiffness value, calculated with the same formulas (see literature [3]).

The following types of stiffeners can be used:

- Web stiffeners

- T – stiffener

- L – stiffener

- Box stiffener

- Channel –stiffener

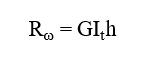

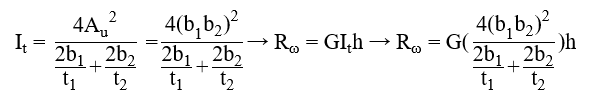

The general formula which can be used to determine the stiffness of the discrete warping restraint is the following:

where,

Rω = the stiffness of the discrete warping restraint

G = shear modulus

GIt = the Saint-Venan torsional constant

h = height of the stiffener

Effect of the different stiffener types

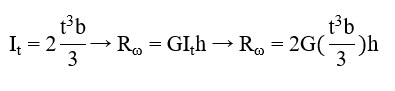

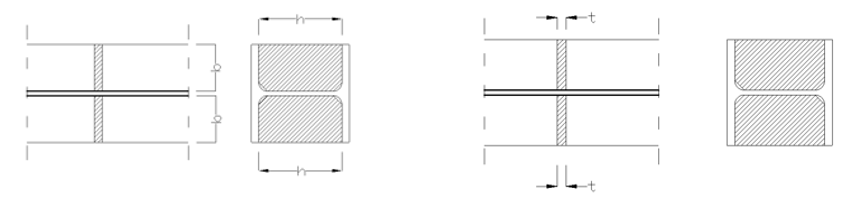

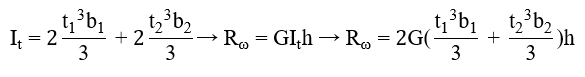

Web stiffener

where

b = width of the web stiffener [mm]

t = thickness of the web stiffener [mm]

h = height of the web stiffener [mm]

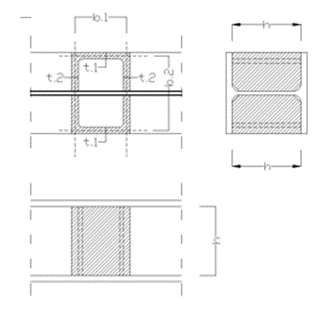

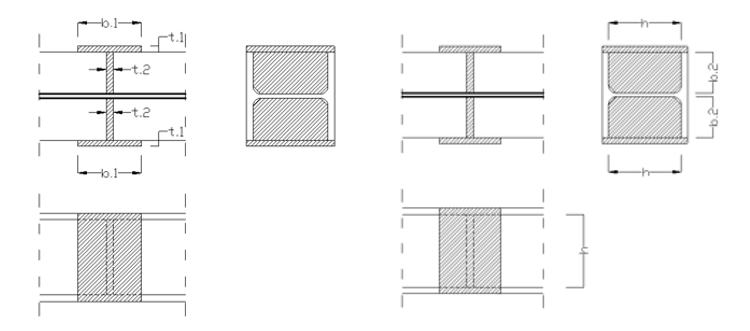

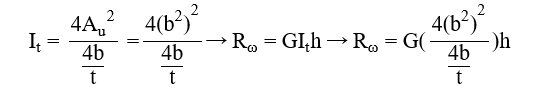

T – stiffener

where

b1 = width of the battens [mm]

t1 = thickness of the battens [mm]

b2 = width of the web stiffener [mm]

t2 = thickness of the web stiffener [mm]

h = height of the web stiffener [mm]

L-stiffener

where

b = width of the L-section [mm]

t = thickness of the L-section [mm]

h = height of the L-section [mm]

Channel stiffener

where

b1 = width of channel web [mm]

t1 = thickness of channel web [mm]

b2 = width of channel flange [mm]

t2 = thickness of channel flange [mm]

h = height of the web stiffener [mm]

Numerical example

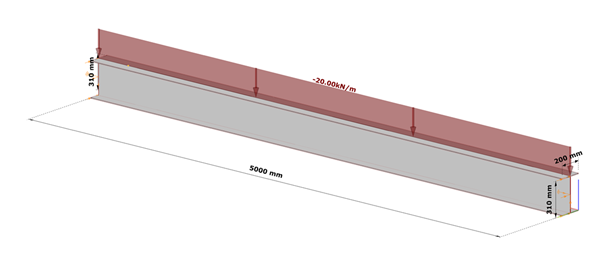

The following example will show the increase of the lateral-torsional buckling resistance of a simple supported structural beam strengthened with a box stiffeners. The effect of such additional plates can be clearly visible when shell finite elements are used.

Shell model

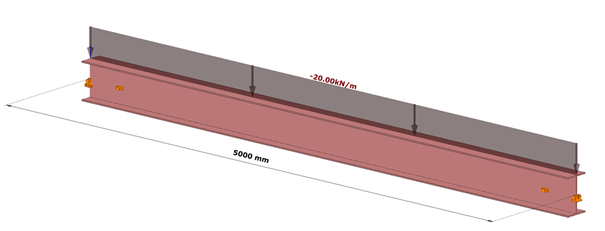

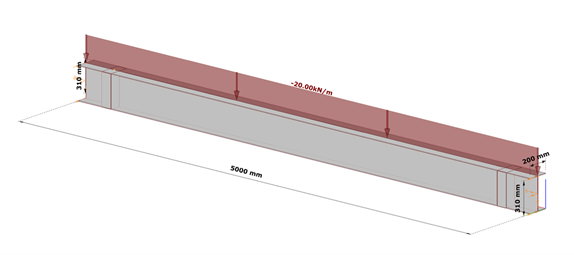

Fig. 7 shows a simple fork supported structural member with welded cross-section modeled with shell finite elements and subjected to a uniform load along the member length acting at the level of the top flange.

Table 1. and Table 2. contain the geometric parameters and material properties of the double symmetric I section. The total length of the beam member is 5000 mm, the eccentricity of the line load is 150 mm in direction z.

| Name | Dimension | Value |

|---|---|---|

| Width of the top Flange | [mm] | 200 |

| Thickness of the top Flange | [mm] | 10 |

| Web height | [mm] | 300 |

| Web thickness | [mm] | 10 |

| Width of the bottom Flange | [mm] | 200 |

| Thickness of the bottom Flange | [mm] | 10 |

Table 1: geometric parameters

| Name | Dimension | Value |

|---|---|---|

| Elastic modulus | [N/mm2] | 200 |

| Poisson ratio | [-] | 10 |

| Yield strength | [N/mm2] | 300 |

Table 2: material properties

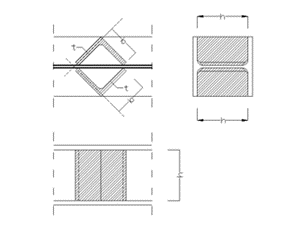

Box stiffener

The box stiffeners are located near the supports as can be seen in Fig. 8. Table 3. contains the geometric parameters of the box stiffeners.

| Name | Dimension | Value |

|---|---|---|

| Width of the web stiffener | [mm] | 100 |

| Thickness of the battens | [mm] | 100 |

| Total width of the box stiffener | [mm] | 200 |

| Height of the plates | [mm] | 300 |

| Thickness of the plates | [mm] | 10 |

Table 3: geometric parameters of the box stiffeners

7DOF beam model

The same effect in a model using 7DOF beam finite elements can be obtained when discrete warping spring supports are defined at the location of the box stiffeners.