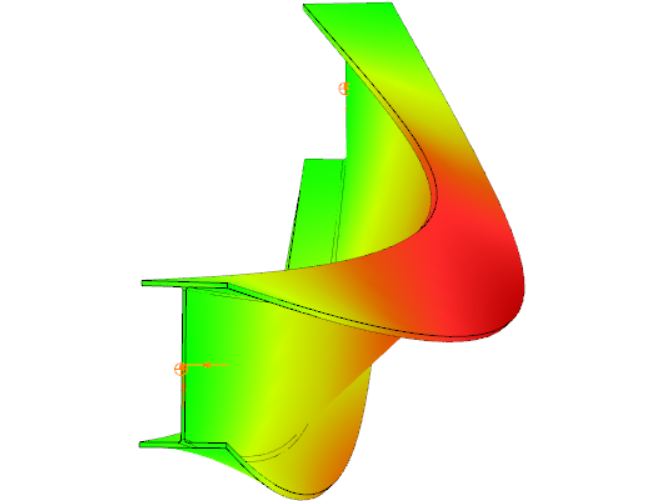

Introducing the one of the winners of The Steel Lion Award 2024. The article includes a detailed case study of Pangolin design for the creation and design of formwork structure.

THE CHALLENGES OF SPECIAL FORMWORK

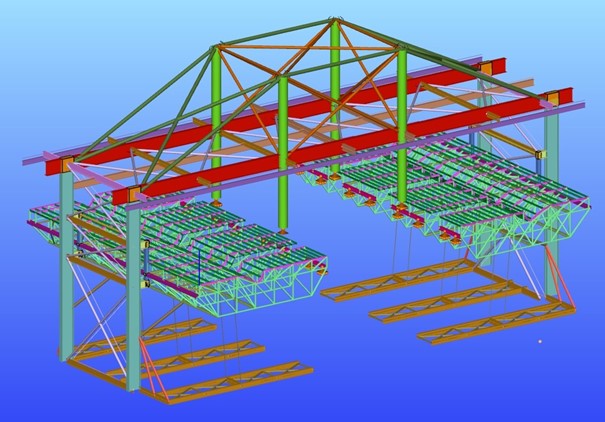

Control throughout the design process is crucial, and even more so when it comes to structures whose loads change throughout the design process, as they are the result of a phased analysis that aims for an optimum.The field of special formwork is one of these areas.

Structures that: must support large loads (weight of fresh concrete) without showing large deformations to obtain the required concrete geometry, with the lowest possible weight so as not to stress the base structure, and which depend on environmental, production, technical conditions, etc.

The design of elements can become a constant back and forth of data between the calculation office and the design office, almost until the last day of the project.

STRUCTURAL CONCEPT

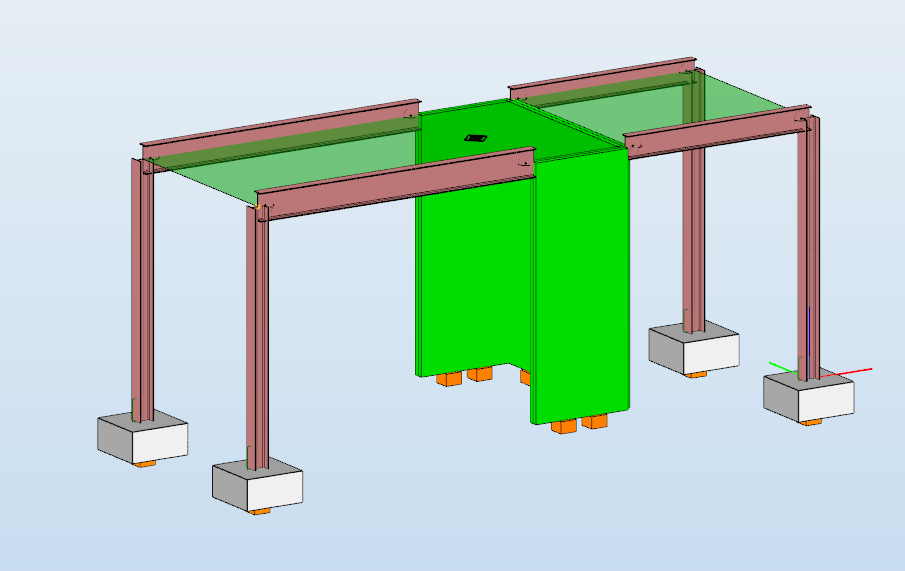

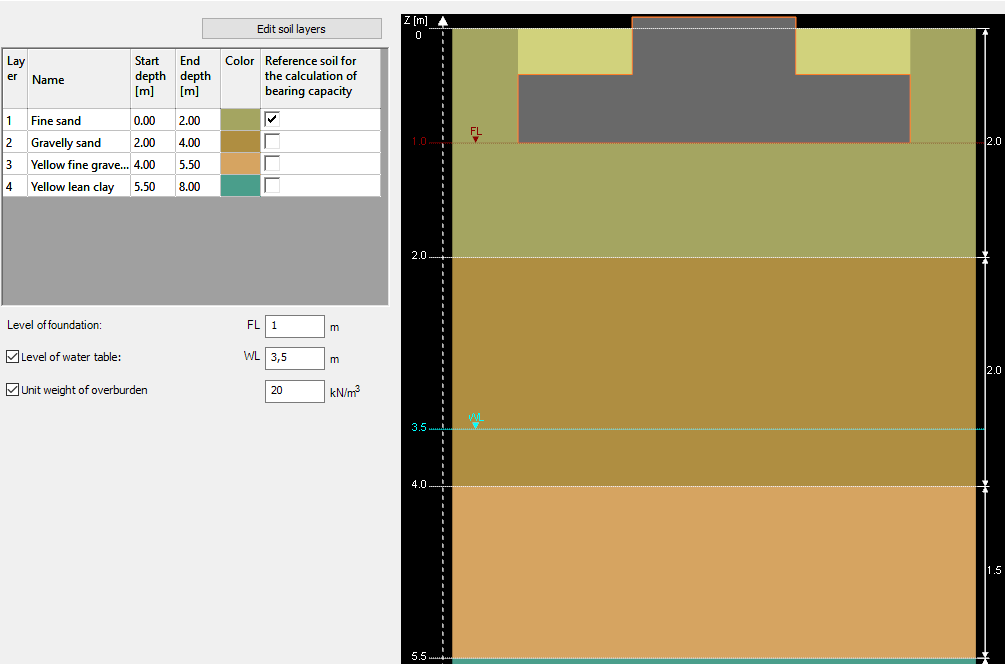

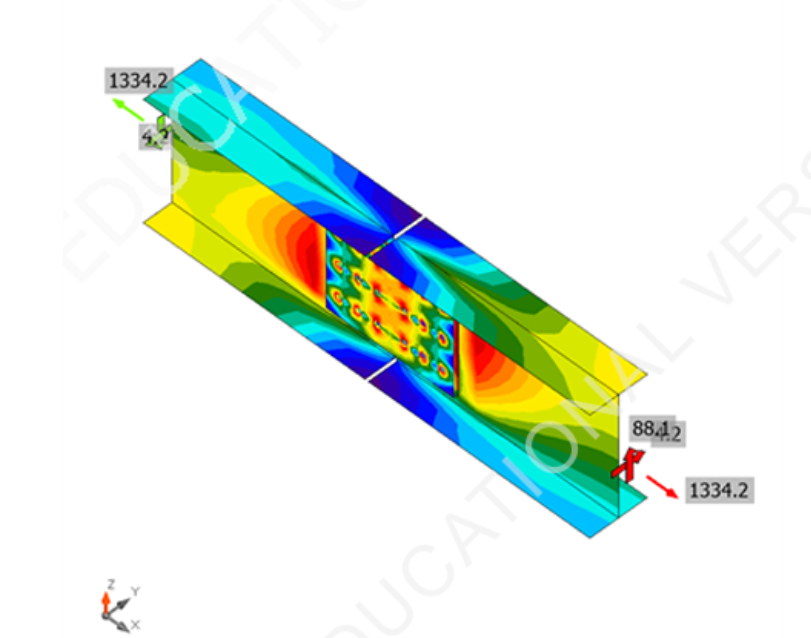

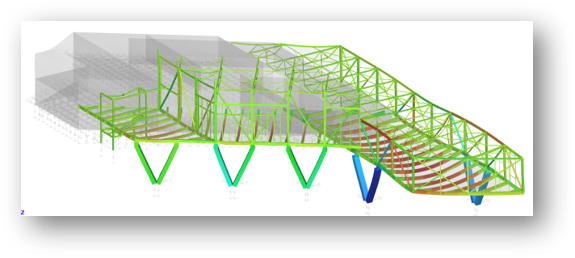

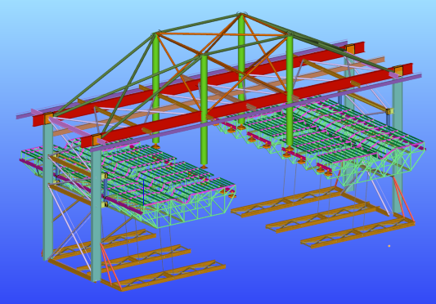

The structure under study is essentially simple (as the initial conception of any structure should be). It is a central structure supported on the central box girder of a bridge deck and can support the load transmitted by two 12 m long cantilever elements, which serve as formwork for the deck’s flanges and as a working platform for the installation of other structural elements.

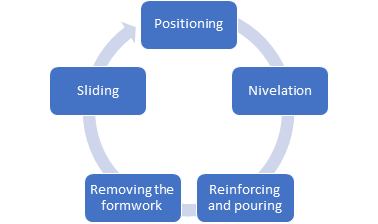

This structure would be sliding on the central box girder. The formwork workflow would be as follows:

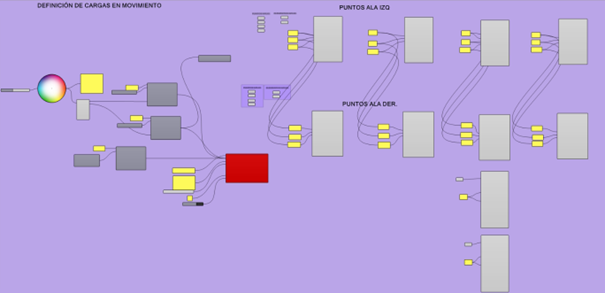

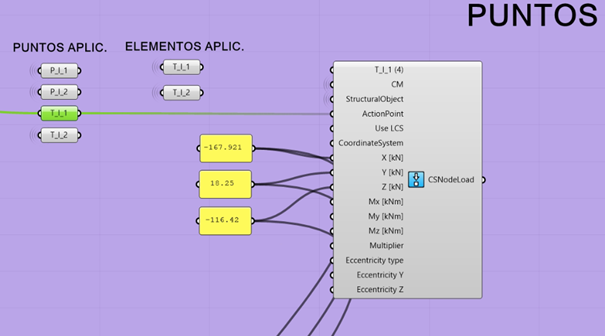

Each of these described phases generates a set of loads that depends on the procedure with which it is carried out and that the different departments (mechanics, hydraulics, formwork, etc.) generate. These loads, coming from partial models, were introduced at previously agreed points and kept fixed by all departments throughout the project as far as possible.

In a context of short deadlines, centralizing, coordinating and being able to maintain the rhythm of calculation and design of the elements that make up the structure is essential. A correct BIM flow, in which the Structural Designer is the BIM Manager, in this type of projects with very specific loads is a basic requirement that transfers trust and control to our partners and collaborators.

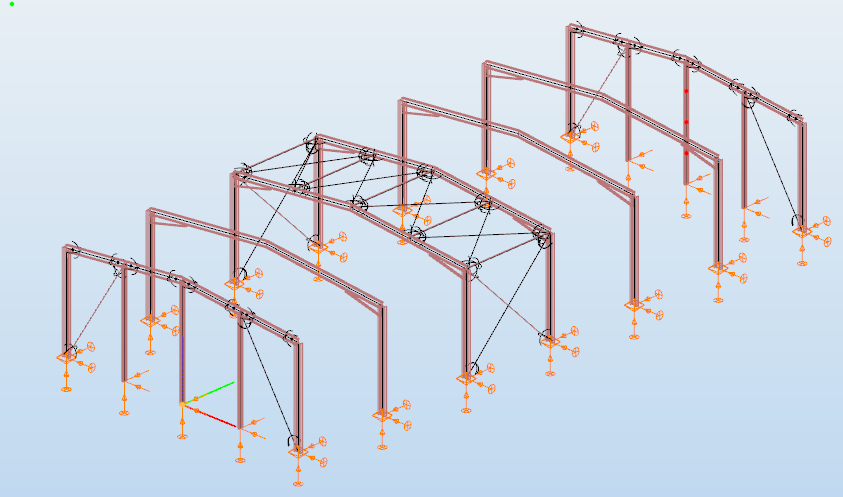

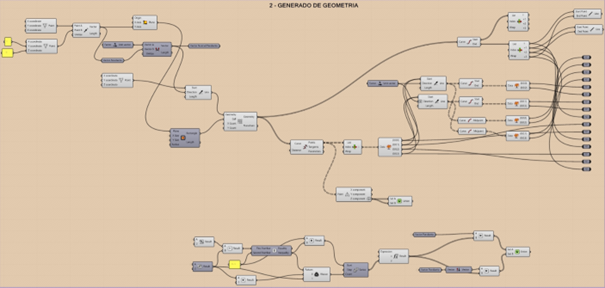

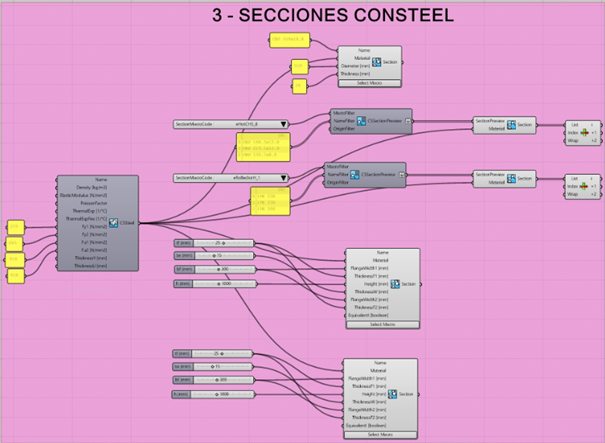

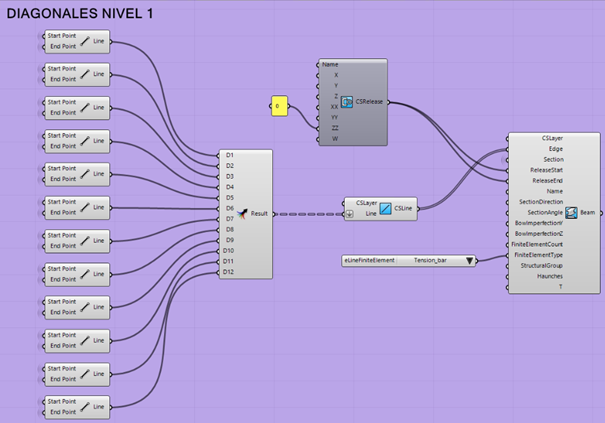

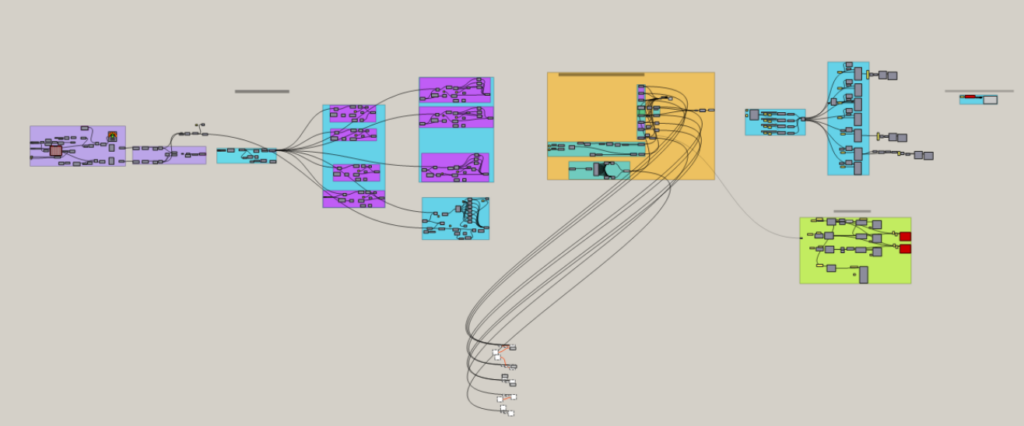

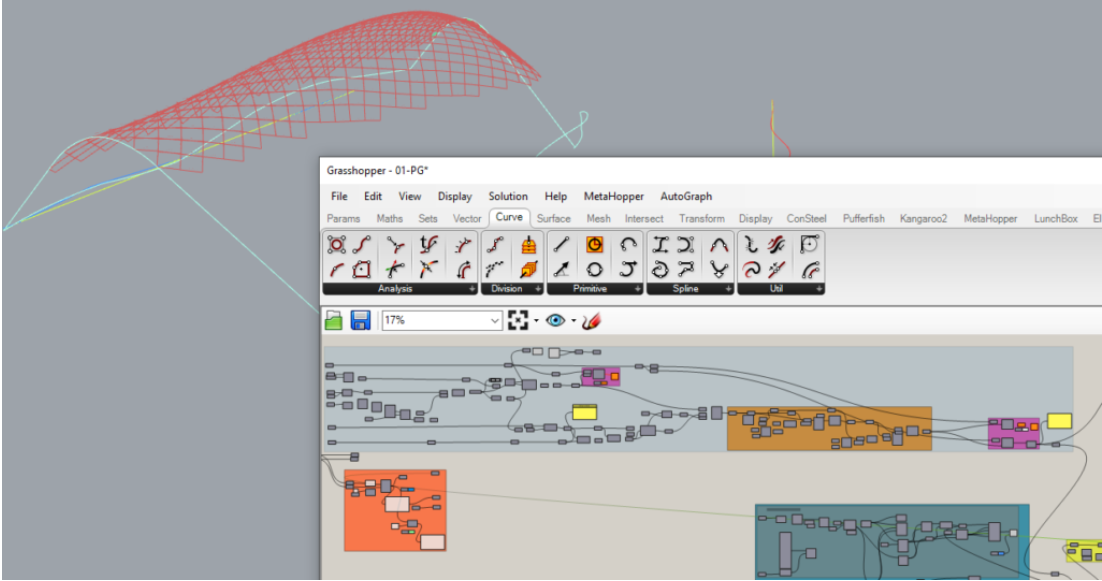

The connection of Consteel through its Pangolin plugin to the Grasshopper graphical programming interface provides the necessary power to combine parametric elements that adapt to a geometry that, as in any project, is continually changing and data management through lists.

GENERATION OF CLEAN AND COMMENTED ALGORITHMS

As in any code, the comments and organization of the algorithm are an important part of the process and consume a large amount of time that at first seems useless but is very profitable when the project extends over time.

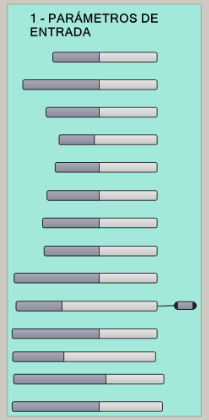

For the case under study, the algorithm groups generated are the following:

- Input parameters: control panel of all the external geometric variables of the algorithm.

- Basic geometry: this group depends only on external geometric variables and should not be manipulated by any member of the team. In this section, the introduction points for other external variables such as loads are generated.

- Data for Consteel: through Pangolin, they are entered as an external variable and through a list:

- The sections to implement in the different frames.

- Releases at frames end.

- Geometry for Consteel: through Pangolin, taking advantage of the geometric entities generated in group 2: lines and points. A subgroup is generated for each type of element.

- Loads for Consteel: through Pangolin they are generated and remain as the final external variable. The parameters to produce are:

- Loads: assigned to the defined points in group 2,

- Load groups,

- Load cases,

- Combinations.

INFORMATION MANAGEMENT

The shared information from the design departments is channeled, centralized and filtered to the model through the fields provided for the entry of external variables by the algorithm manager (structural engineer).

It is important that there is a prior coordination phase with the design team in which the shared data and its format will be established.

CONCLUSIONS

- The use of algorithms that automate and simplify data entry into complex models is a way to reduce errors in the final design phases.

- These algorithms allow sharing models in intermediate design phases that will serve the design department for a better understanding of the behavior of the system and therefore better load optimization.

- The centralization of continuous changes in parametric algorithms allows obtaining structural models in constant evolution.

If you want to get inspired by the work of other submitted Structural Engineers, take a look at all projects on the website of The Steel Lion Award.

Introducing the student prize winner of The Steel Lion Award 2024. The project introduces the parametric design and was created by Darius Dumitraşcu, a final year student from Romania.

GENERAL DATA

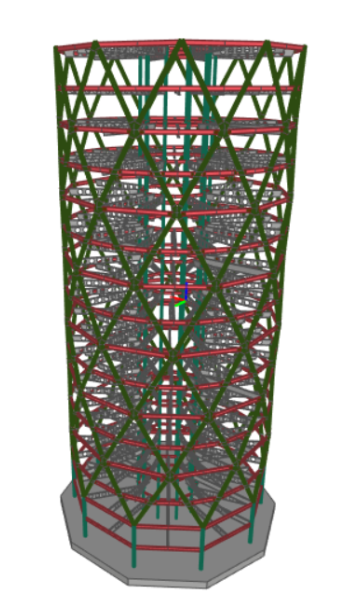

For Darius Dumitraşcu, the winner of the Student Award, the task was the design of an office building, based on a steel structural system. He proposed to create a fictional building, giving him the freedom of creating any kind of geometry for the structure, which provided him an opportunity to approach the design with parametrization more freely. The final structure was inspired by The Gherkin from London, and it’s diagrid structure.

The next step was to build a parametric model which could help him build up and analyze several models with slightly different geometries by only changing a few parameters, and could be used to generate the final model.

THE SCRIPT

- Definition of starting parameters

- Geometry generation

- Data sorting

- Tekla model generation

- Defining Consteel loads

- Defining Consteel elements

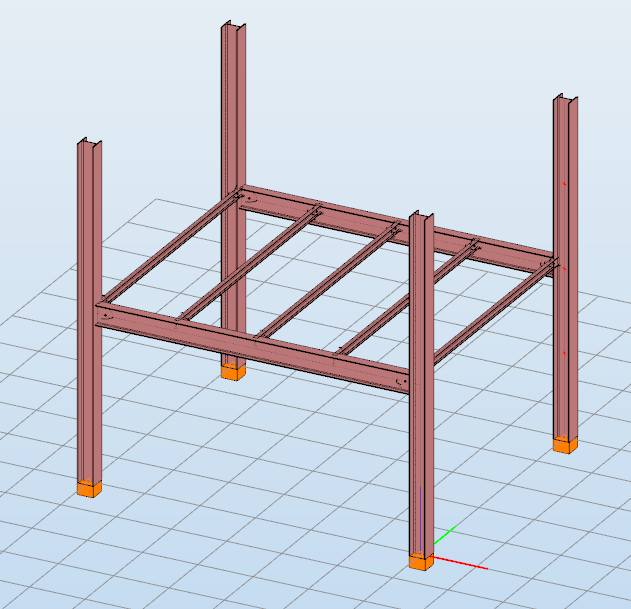

THE GEOMETRY

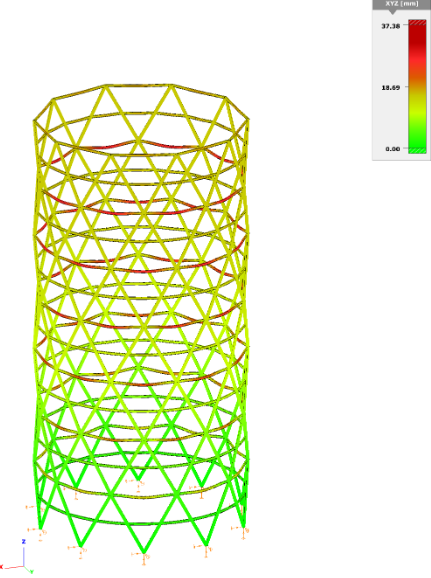

To simplify the parametrization process, he decided to create the base of the structure on a regular polygon with n sides, which gave him the chance to play with the density of the diagrid columns and see how many are necessary. The base form determined the rest of the geometry, distribution of beams and angle at which the floors are rotated by. In total, the script took 3 weeks to build, and it allowed to create and analyze any form in minutes.

LOAD DEFINITION

The Romanian norms and Eurocode were used to define the loads of the structure, according to an office building. The load from mechanical machines is 1.5 kPa. The loads were applied automatically thanks to the Pangolin plugin, which allowed the generation of the load combinations for each model as well, except seismic load and its combinations.

GENERATING THE CONSTEEL MODEL

Thanks to the parametric script, he was able to create models instantly with element end conditions, their exact position, loads, and load combinations. Then these models could be analyzed by the global check module, and see the level of utilization of the elements, find the critical points of the structure, and if needed, make slight changes in the model to make it more optimal.

After selecting the final model, thanks to the communication of Consteel with IDEA StatiCa, it was easy to create the models of the connections and calculate them in IDEA StatiCa.

The skeleton of the Tekla Structures model was built parametrically, which was followed by the modeling of the connections. These steps led to the final drawings and the finalization of the project.

CONCLUSION

The parametric model made it possible to create and analyze different configurations of the structure in a short time. The complexity of the structure was facilitated by the parametric script. Overall, the three-week build time of the script paid off, as the final models were created faster and the optimal shape of the structure could be found. The script can also be used for similar tasks for any n-sided polygonal structure.

If you want to get inspired by the work of other submitted Structural Engineers, take a look at all projects on the website of The Steel Lion Award.

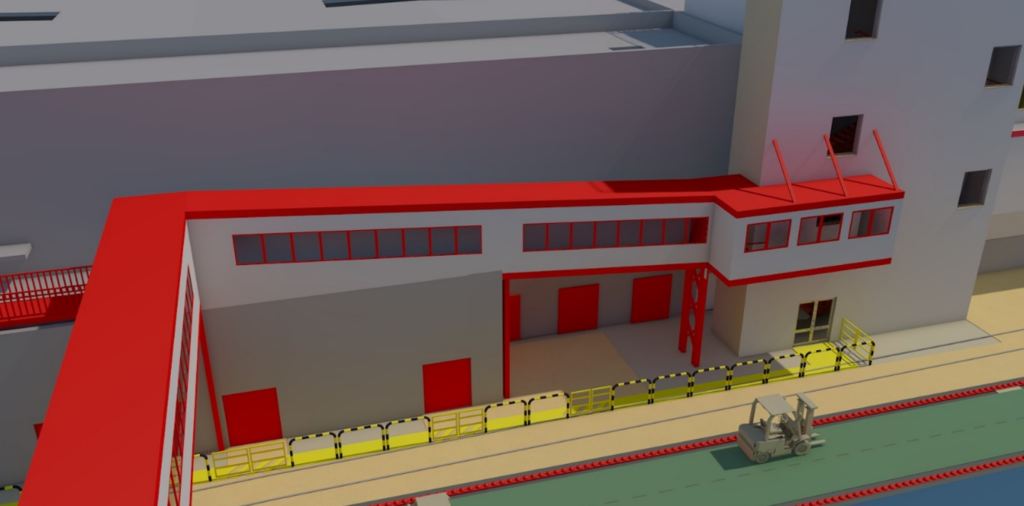

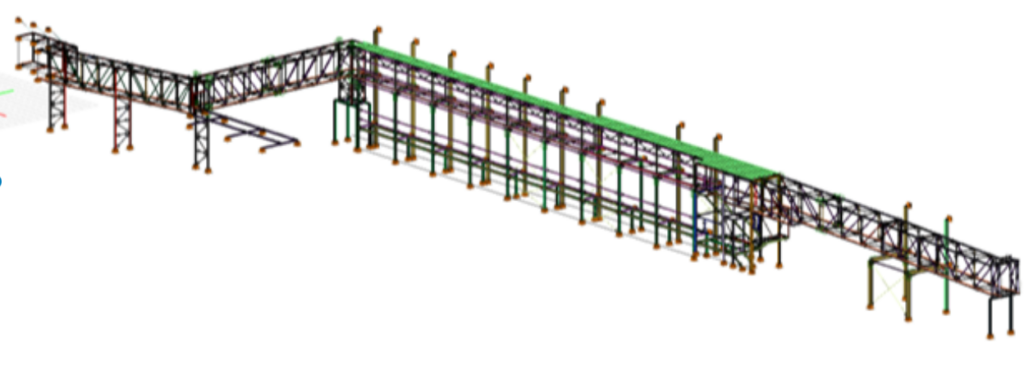

Introducing the 2nd place winner of The Steel Lion Award 2024. The project describes the design and dimensioning of a pedestrian bridge support structure. The project was created by Kornél Kiss, Structural Engineer, collaborator of Eurostatik R Engineering and Construction Ltd.

GENERAL DESCRIPTION AND BACKGROUND

The client was looking for a solution for pedestrian traffic in their existing production halls, separated as much as possible from forklift and truck traffic in the yard.

The enclosed, heated bridge starts from a staircase and leads to the roof of the next building. An open, steel-framed walkway bridge connects to an open walkway podium, also steel-framed, on the existing roof. From the roof, the enclosed walkway turns away, above the walkway between the two large hall buildings. The corridor on the upper floor will be built on top of and above the existing process corridor. At the end of the technological corridor, a staircase will be constructed to allow access to the ground floor and the courtyard area. After the staircase, the walkway continuing the first-floor level will lead to the first floor of the office building. A reinforced concrete slab floor with trapezoidal slabs will be constructed along the entire length of the corridor.

In designing the geometry, the architects had to deal with the height differences between the incoming and outgoing levels of the structure, which had a major impact on the supporting structure. The high, low and turning points are the main critical nodes of the structure.

Furthermore, one of the client’s important requirements was that the individual production units should be as large as possible, to minimize disruption to internal and external traffic during the construction process.

Loads and effects were defined according to the standard.

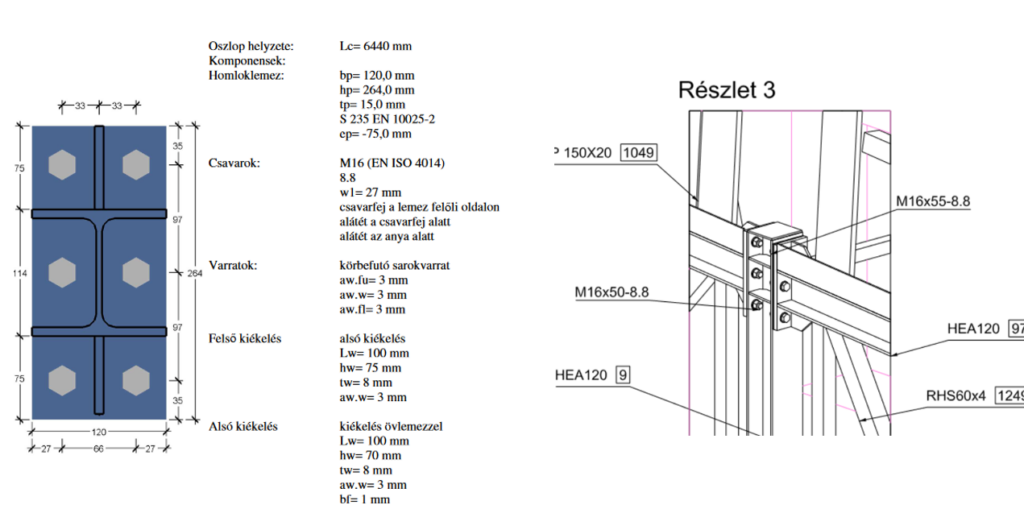

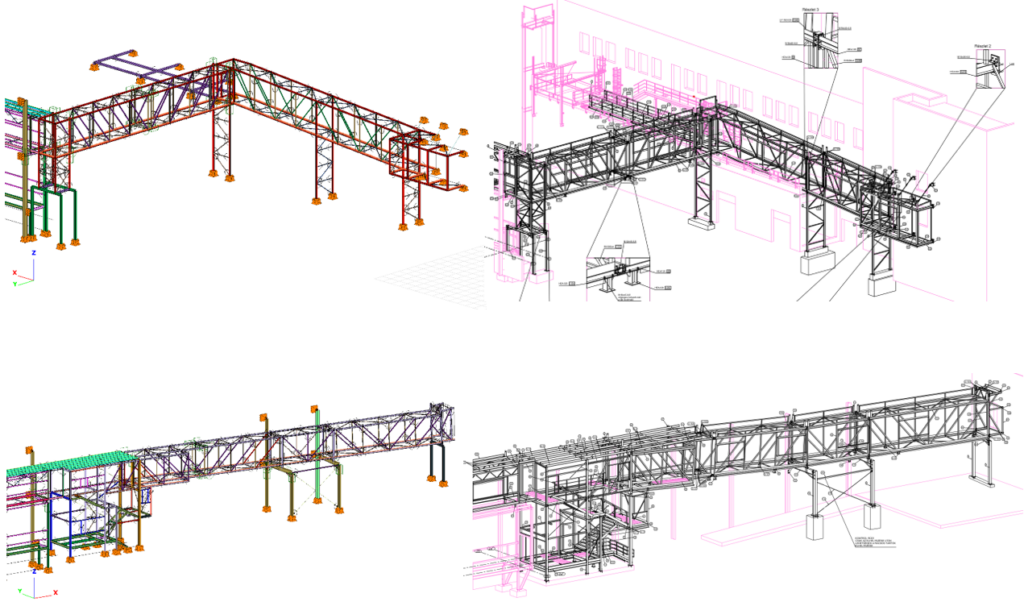

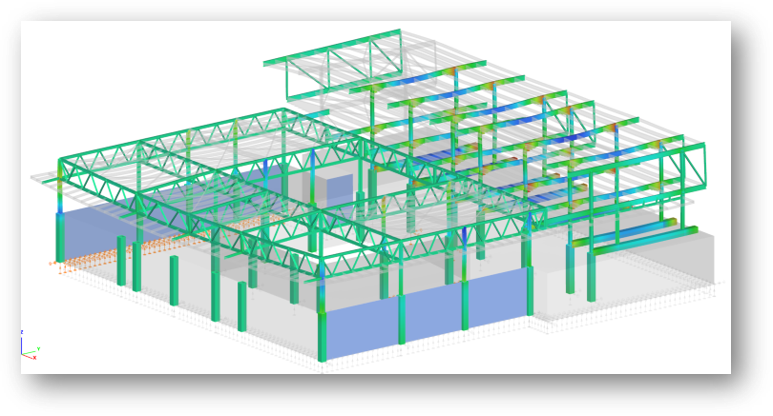

CREATING A CONSTEEL MODEL

The main input data was the geometry taken from the architect and a geodetic survey of the existing and associated structures. The first, still “rough” geometry was created in Advance Steel, it was important to finalize the geometry and communicate with the designers.

Once the geometry was finalized, the Consteel model was created using an IFC file, which was successful with surprising accuracy and minimal deviations (gap between bar memebers).

The structural design was carried out using both Consteel and Advance Steel software. The sections were designed in Consteel. The selected sections were then transferred back to Advance Steel for connection design, after which their feasibility and effect were checked again in Consteel.

THE CONCLUSION, PLANS AND THE OUTCOME

The design duration was 2-3 months, with 1 structural engineer designing the steel structure and 1 structural engineer designing the foundations.

With Consteel, the structural complexity could be easily understood. Using software tools such as buckling sensitivity, effect and design of purlin lines, and finally checking the design of the main connections, the influence of connections’ rotational stiffness on the structure simplified the process.

If you want to get inspired by the work of other submitted Structural Engineers, take a look at all projects on the website of The Steel Lion Award.

The annually organized International Consteel Meetup is achieving greater success each year. In 2024, the event had nearly 200 participants and almost 300 registrants. Attendees could participate in numerous professional demonstrations, which included practical examples, featuring the works of The Steel Lion Award applicants and the award-winning projects.

THIS YEAR’S ANNUAL CONSTEEL MEETUP HAS ALSO TAKEN PLACE

The annually held International Consteel Meetup is achieving greater success each year. This year the event had nearly 200 participants and almost 300 registrants. Attendees could participate in numerous professional demonstrations, which included practical examples, featuring the works of Steel Lion Award applicants and the award-winning projects.

The day began with a theoretical summary comparing 6 DOF and 7 DOF finite elements, and The Steel Lion Award submissions were presented, with the winners announced. Next up there was a more practical demonstration on Consteel solutions for everyday engineering challenges. By the leading engineers of ConSteel Solutions the goal of the presentations was to show how the joy of structural design can be rediscovered behind the daily routine solutions.

After the lunch break, attendees could hear from David Lewandowski of bim.GROUP about the parametric design workflow of the Alba Arena steel structure, the Pangolin award-winning project last year. This was followed by insights into Grasshopper scripting and Pangolin case studies, concluding with a live demonstration of the wind simulation plugin, which was shown before its final integration into the software.

THE LIST OF THE STEEL LION AWARD WINNERS’

A total of 60 excellent projects were submitted for The Steel Lion Award by 78 Structural Designers from 35 companies across 6 European countries, complemented by the valuable diploma theses of 6 students.

After extensive evaluations, our jury succeeded in selecting the structural designs that showcased a creative solution in an exceptionally strong field.

- st place: Covasna SPA – Balneological Center – KÉSZ Romania

- nd place: Pedestrian bridge – Eurostatik R Ltd.

- rd place: Structure of a house – I5 Ingenieria

The winner of the Pangolin Award: Cantilever formwork for the flanges of a deck viaduct – Grupo Tecozam (Asistencia Global de Ingenieria & Gestion Y Actividades Secozam)

The winner of the Student Award: Design of an office building based on steel structure – Darius Dumitrascu (Tehnical University of Cluj-Napoca)

If you want to get inspired by the work of other submitted Structural Engineers, take a look at all projects on the website of The Steel Lion Award.

In the first quarter, we have collected some new model examples on topics of Grasshopper and Pangolin, own NA settings, pre-engineered Metal Building, and how to build models your own script, available for free download from the Knowledge Base.

Integrate structural model and analysis in Grasshopper

Did you know that Consteel provides a plugin to integrate structural modeling and analysis into your parametric Grasshopper definitions?

How will you possibly work in Pangolin? See the related videos on our YouTube channel, starting with the ‘Introducing Pangolin‘ video.

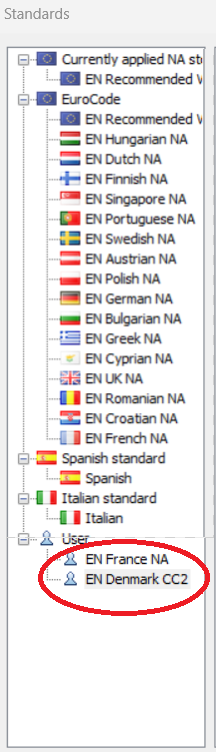

Create your own NA settings

Did you know that Consteel already supports most of the countries which have adopted Eurocode design standard?

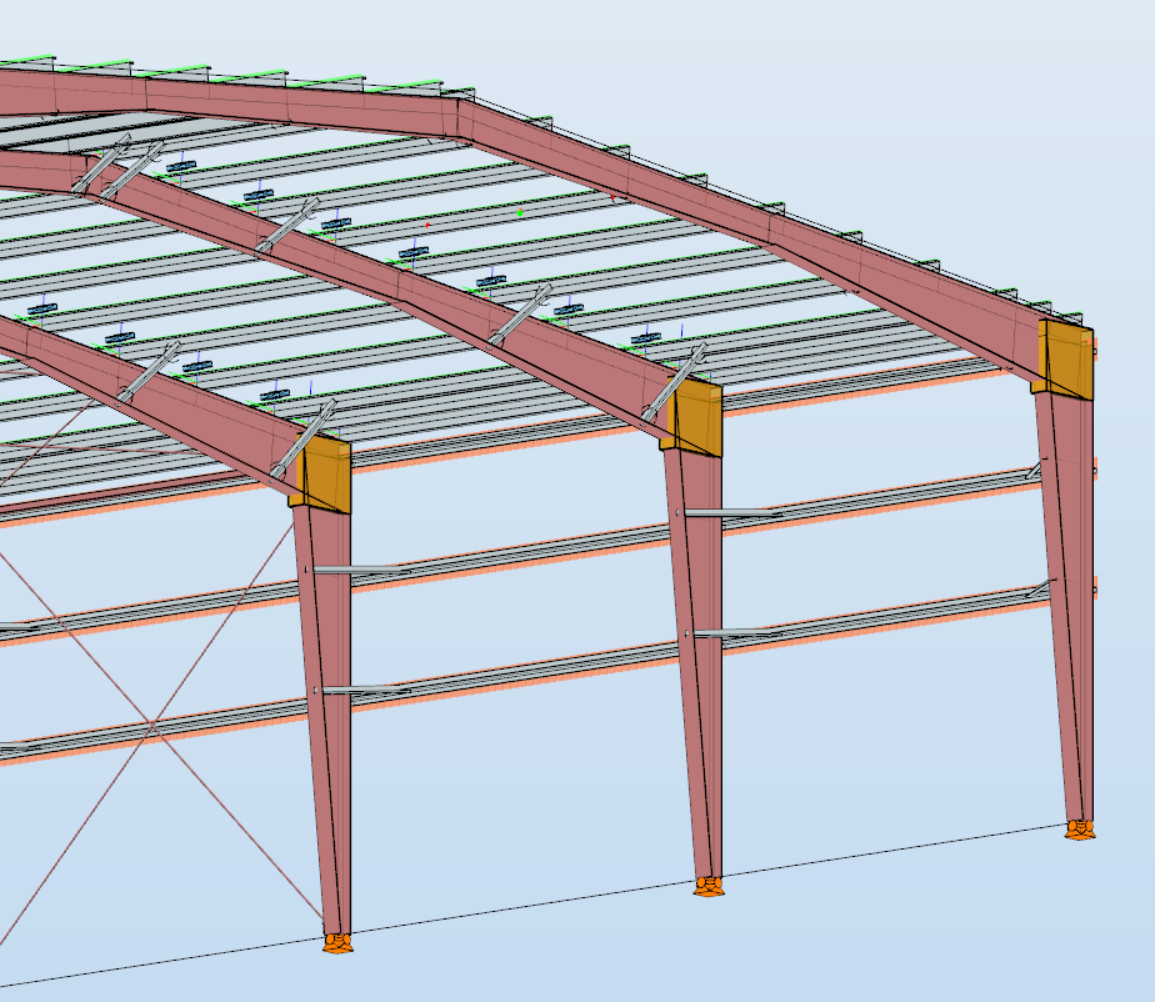

Design a pre-engineered Metal Building

Did you know that you can use Consteel to design a pre-engineered Metal Building with all its unique characteristics, including web-tapered welded members, the interaction of primary and secondary structural elements, flange braces, shear and rotational stabilization effect provided by wall and roof sheeting?

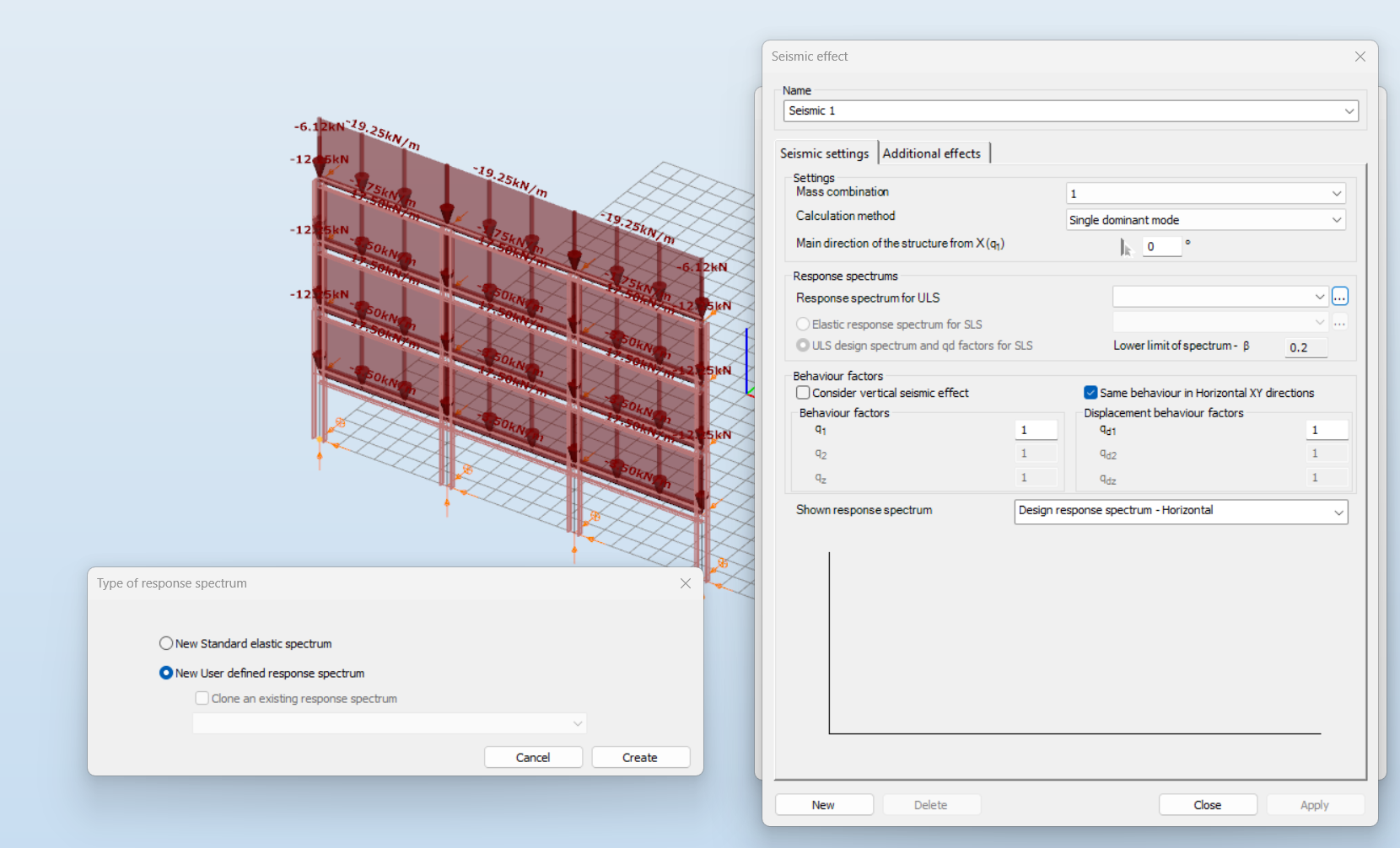

User-defined response spectrum

Did you know that in addition the standard Type 1 and Type 2 response spectrums defined by Eurocode 8, you can use also user-defined spectrums with Consteel?

To see what else the Consteel software can do, check out the features.

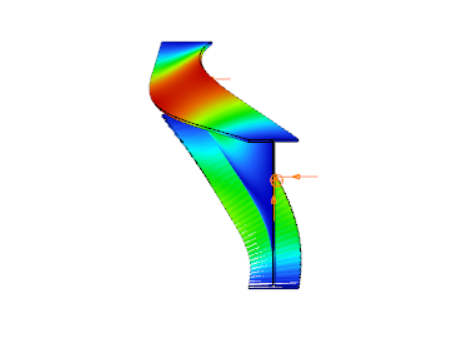

Have you ever heard about the ‘General Method’? Consteel recommends to use the General Method from EN 1993-1-1 for the evaluation of out-of-plane strength of members and sturctures. Free model examples and information are available in the Knowledge Base.

What is a ‘General Method’?

General Method is an alternative design method to consider the interaction of axial compression with major-axis bending for general buckling situations, where the main interaction formulas are not applicable.

This basically includes every member with monosymmetric or asymmetric cross-sections or with cross-sections not uniform along the length (welded tapered sections) or laterally stabilized by sheeting or anything else without providing full fork supports.

The General Method is fully supported by Consteel and provides an automated buckling verification possibility. Of course, for the use of the General Method in a general case the traditional 12DOF beam finite elements are not applicable. If you are interested, take a look at the example.

Our software recommends to use this method from EN 1993-1-1 for the evaluation of out-of-plane strength of members and sturctures.

When linear buckling eigenform affine imperfections are used, Consteel can scale automatically the selected eigenmodes to perform a Eurocode compatible design, and you can even combine several imperfections. In addition, the scaled imperfection based 2nd order approach is available.

To see what else the Consteel software can do, check out the features.

Consteel 17 has been released! The new version concentrates entirely on usability, including improvements for efficient modeling, load adjustments and simplified calculations, broadened design result display and software interactions, and so much more. Watch our comprehensive guide!

We’ve already summarized the new features in our previous blog article, but we’ve also made a video with English and Hungarian subtitles. You can find the subtitles in the settings menu on our YouTube channel! Here are some highlights for inspiration:

? Automatic model portions

? X-brace

? Improved handling of Load Transfer Surface loads

? Extended and unified design results

? New environment for software interactions (AxisVM plugin)

? Numerous new Descript commands

? Improvements for efficient modeling

? Steelspace developments (detailed model compare, clipping plane, advanced collaboration management)

Watch our comprehensive guide on the new version

In this comprehensive video, we walk you through a step-by-step workflow guide, demonstrating how to leverage Consteel 17 to its full potential.

Explore the new features for free

Download the new version now!

DownloadIf you are new to Consteel, you can explore the new features easily. After the release of Consteel 17, the new developments will be automatically available in our free trial version.

Our users who use our software with online protection will automatically have access to the latest version after installation. Consteel users with USB dongle protection will receive the necessary information to upgrade when the new version is released. For any problems with the update, please contact our support team.

The Steel Lion Award is an international competition for steel structural engineers until April 5 – students can also apply in a separate category. This award recognizes creative parametric solutions in the field of steel structure design, promoting innovation, creativity, and excellence. The winners will be announced at the International Consteel Meetup on April 11, where the presentations will focus on what we are passionate about. This year the competition is open for submissions again so don’t hesitate to apply!

The history of the award

The award was launched last year with great success and 30 steel structure models from different industries were submitted in 2022. For two years, The Steel Lion Award will include all ConSteel-related competitions and contests, including the Hungarian User Day contest or Diploma Competition, to create a high-level, internationally recognized professional or graduate award.

The Steel Lion Award is an innovative program designed to recognize and motivate skilled structural engineers from around the world to showcase their best projects at Consteel. Considering our extensive user base, which includes both local and international markets, we want to give all users the opportunity to enter their exceptional work into the competition.

This year, you can submit entries for the award until April 5, students can enter their diplomas alongside Hungarian and international projects, which will be subject to a separate evaluation.

In 2022, we have created a website where the submitted and collected models can be viewed in a spectacular online viewer. For more details on this prestigious award, please read the website of the Steel Lion Award.

How to apply with your project?

The size of the project or the size of the Consteel model is not a key factor during the evaluation, so smaller projects with creative, unique solutions are warmly welcome. To apply with your project, it is also free for everyone in 2024, with the prerequisite that the company must have a live Consteel license. A company can apply for the award with more than one project, and in that case, an application form must be completed for each project. The end of structural design (e.g., finished model) for all projects should be within the previous 5 years. Applications will close on April 5 and will be reviewed by the professional jury.

An international ConSteel team of structural engineering professionals and academic professors will evaluate the submitted projects. All projects that use scripting technologies (Pangolin or Descript) in their solution will be automatically evaluated for the Pangolin Award. We believe that this new technology is the future of structural steel design and that it is essential to promote its uptake and spread within the profession. The winners will be announced during the International Consteel Meetup on April 11. The detailed program of this event will be available soon. The detailed program of the event is available.

APPLY FOR PROJECT CATEGORYHow to apply with your diploma?

To apply with your diploma, your thesis should be written between January 2022 and February 2024. If you are a student or have graduated in the last 2 years, you do not need to have a live Consteel license. The diplomas will not be evaluated together with the real projects submitted by experienced professionals. Applications will also close on April 5.

APPLY FOR STUDENT CATEGORYWinners announced on the International Consteel Meetup

The winner of each category will be announced at the International Consteel Meetup on April 11, 2024. We believe that the power of community multiplies the performance of individuals. That is why we consider community building important in the field of structural engineering, and an important step is to share our results with each other. This is perhaps the most valuable part of The Steel Lion Award, to show each other what and how we work in Consteel.

This year we won’t be focusing on structural design as a work or job. We would like to focus on structural design as a passion! We would like to discuss what can make our beloved profession an exciting and fascinating activity.

Come and let us show you how Consteel supports what we think is the best part of structural engineering!

Turn your passion into efficiency!

RegisterThis April 11, at the International Consteel Meetup, we won’t be focusing on structural design as a work or job. We would like to focus on structural design as a passion! We would like to discuss what can make our beloved profession an exciting and fascinating activity. We will also announce the winners of The Steel Lion Awards in this day.

Enjoy your structural design!

We believe that the power of community multiplies the performance of individuals. That is why we consider community building important in the field of structural engineering, and an important step is to share our results with each other. This is the most valuable part of The Steel Lion Award, to show each other what and how we work in Consteel. If you haven’t heard of the later, you can read more about it in our previous article.

In addition to experienced Consteel users, any interested engineers, companies, or students open to new technologies are also welcome to join. Come and let us show you how Consteel supports what we think is the best part of structural engineering!

Turn your passion into efficiency!

The event is free but registration will be required. For more details and program, scroll down!

RegisterPresenters

ConSteel Solutions

CEO

ConSteel Solutions

S. Research Engineer

ConSteel Romania

Development Engineer

bim.GROUP

Structural Engineer

Program

The presentations will be in English only.

9.30 – 11.00

Components of the real experience of structural design in Consteel – how to study and understand the true structural behavior of your model, and control your design – József Szalai PhD, CEO, ConSteel Solutions Ltd.

11.00 – 11.30

The Steel Lion Award – presentation of the submitted projects and the winners – József Szalai PhD, CEO, ConSteel Solutions Ltd.

11.30 – 1.00 LUNCH BREAK

1.00 – 2.30

Unconventional solutions for conventional structures – Find the engineering challenges and elegant solutions in everyday design tasks

Bálint Vaszilievits-Sömjén, Senior Research Engineer, ConSteel Solutions Ltd.

2.30 – 3.00

Guest presentation: Parametric design workflow of the steel structure of Alba Arena, Hungary

Dávid Lewandowski, Structural Engineer, bim.GROUP Ltd.

3.00 – 3.30

Grasshopper scripting case studies – 5 years of Pangolin

Ádám Kis, Development Engineer, ConSteel Solutions Ltd.

3.30 – 4.15

New wind simulation tool – Integrating CFD to practical structural design

Ádám Kis, Development Engineer, ConSteel Solutions Ltd.

Have you registered for the event? Then let us know if you want to participate!

RegisterIn October, we have collected 4 new example models on topics of design pad foundations, support settlement, smart link elements, and how to build models your own script, available for free download from the Knowledge Base.

Design pad foundations

Did you know that you can use Consteel to design pad foundations?

Calculate support settlement

Did you know that you can use Consteel to calculate support settlement?

Apply your own scripts to build models and perform calculations

Did you know that you can use Consteel to apply your own scripts to build models and perform calculations?

Build 3D models with smart link elements

Did you know that you could use Consteel to build 3D models with smart link elements which automatically adapt the model when profiles are changed?

To see what else the Consteel software can do, check out the features.