Did you know that you could use Consteel to design web-tapered members?

Tapered members are widely used in the economic design of steel-framed structures, such as industrial halls and warehouses, because they make it possible to save material while still ensuring structural strength and stability. With Consteel’s dedicated Tapered Member function, you can model, analyze, and verify these members efficiently, supporting both everyday engineering practice and advanced stability checks.

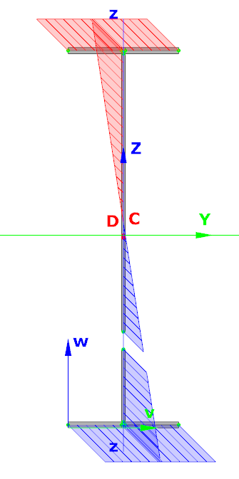

In Consteel, tapered members are line members with welded I or H, box, or cold-formed C sections. Hot-rolled and other macro sections cannot be tapered. Their section height can vary linearly along the member length, making them suitable for realistic structural modeling.

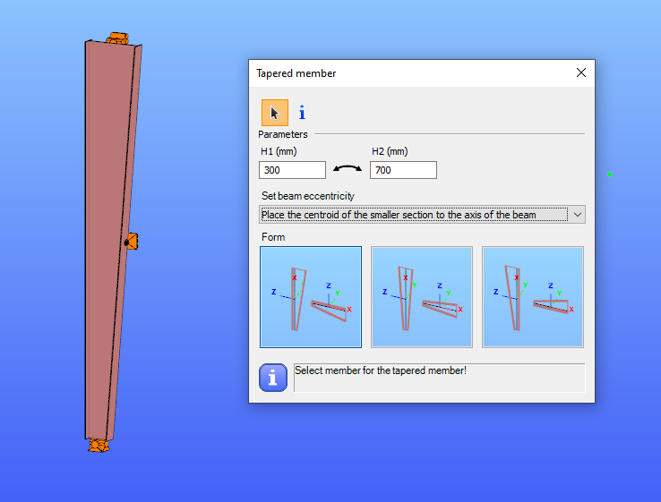

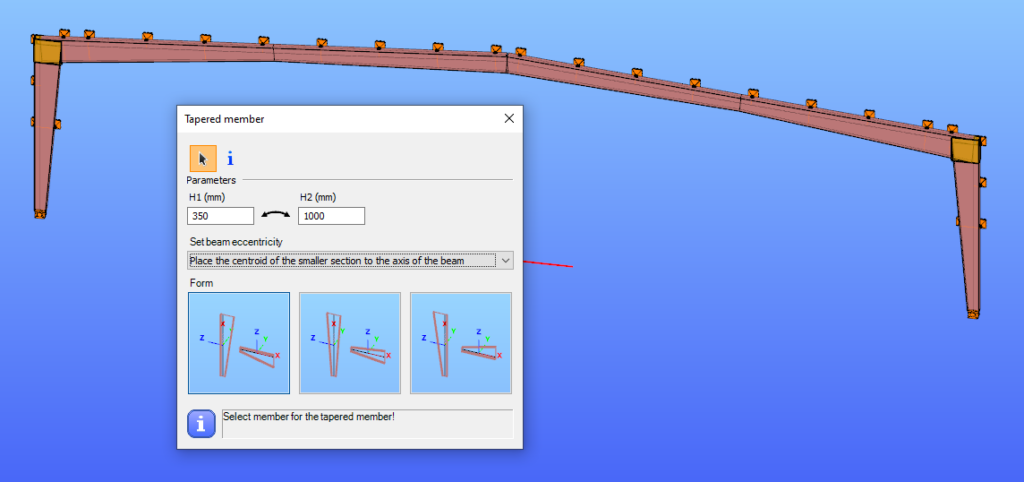

It is best to start with a section close to the smaller end of the taper. The start height (H1) applies at the beginning of the member, and the end height (H2) at the other end. If either value is less than half of the original section height, Consteel automatically resets it to 0.5 times the original. H1 and H2 can be swapped easily with the dedicated icon to reverse the taper direction.

The placement of a tapered member relative to the axis of the original beam is defined by beam eccentricity rules. Consteel offers three alignment options:

- Centroid of the smaller section on the axis – the tapering develops outward from the end with the smaller height.

- Centroid of the larger section on the axis – the bigger end of the member remains fixed to the original axis.

- Centroid of the original section on the axis – one edge of the tapered member coincides with the original section, and the tapering starts from this position.

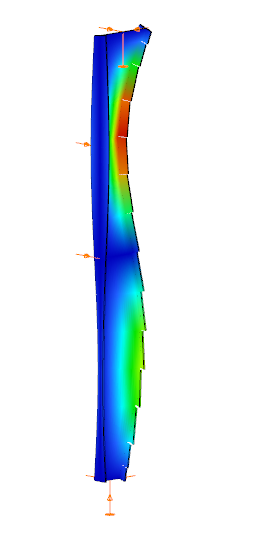

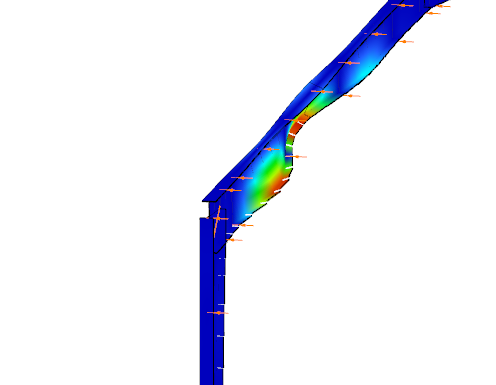

In analysis, Consteel creates tapered sections with the specified start and end heights and places them on the member’s reference line. Unless symmetric tapering is used, this placement is eccentric, which introduces additional effects. At frame joints, for example, extra moments from eccentric axial forces must be considered to maintain equilibrium.

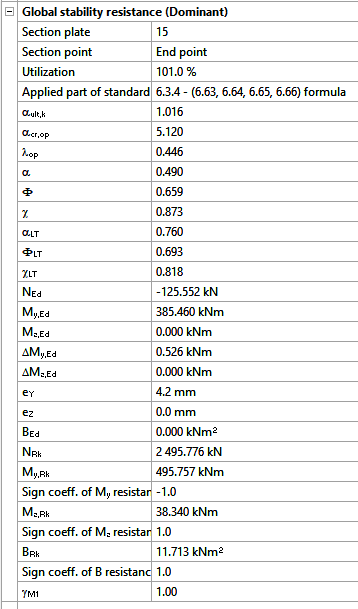

Consteel handles these effects automatically, ensuring realistic results. Symmetric tapering keeps the analysis simpler, while eccentric tapering requires more attention. In all cases, global stability checks should complement sectional verifications to guarantee structural safety.

Download the example model and try it!

Download modelIf you haven’t tried Consteel yet, request a trial for free!

Try Consteel for freeThis paper discusses a combination of best practices and procedures from recent work in Europe and the US, providing rational and economical calculations addressing the complexities associated with frame design using nonprismatic members. Recommendations are provided in the context of US design practice. A primary objective is to achieve maximum simplicity, transparency, and design speed while facilitating rigor of the underlying calculations. The paper provides several focused examples illustrating the recommended design verification procedures.

Click the button below to download and read the full article.

GATEThe portal frames composed of tapered welded I-shaped structural members play important roles in the industrial buildings. The application of the relatively thin plates and the optimized fabrication makes these structures being competitive against the light truss structures at least in the range of 24–36 meters span. Competition has resulted in lesser selfweights using thin plated slender cross-sections, which are sensitive to local buckling. However, the development of structures concerning local buckling was delayed in Hungary by the conservative specifications of the MSz 15024 standard. The application of the new EN 1993 standard may cause radical development in the design of tapered structural elements with relatively thin plates. This paper introduces the methods as well as the advantages of the new design methodology.

Clich the button below to download and read the full article. The article is in hungarian at page 42-55.

gate