The ordinary practice of structural design is based on the use of many empirically introduced safety factors and statistical approaches, considering / applying different standards. As a result, the geometrical model of the buildings and the loads acting on them can often differ significantly from reality because of these simplifications, especially if the geometry of the structure is freeform, which is practically impossible to accurately model and analyse with standard tools.

Detaching from reality can be a legitimate concern for a structural designer which amplifies when it comes to wind load evaluation. Thoughtfully, but structural engineers must be able to respond to the needs of today’s architecture. This is why computational fluid dynamics (CFD) simulation methods are increasingly appearing as an alternative solution for the challenges of non-conventional geometries between the conservative solutions offered by the standards and the experimental way, using wind tunnel tests. For this purpose OpenFOAM as a CFD engine offers a wide range of solutions. Although, for these type of simulations a proper environment is essential, where one can easily define all the necessary parameters to setup a flexible simulation case. This led us to begin the implementation of these solutions into our platforms based on our research in the topic. This lead to a new functionality, where one can define the simulation parameters conveniently, using OpenFOAM as the engine without a comprehensive knowledge regarding its use.

Design code interpretations in the case of free-form structures

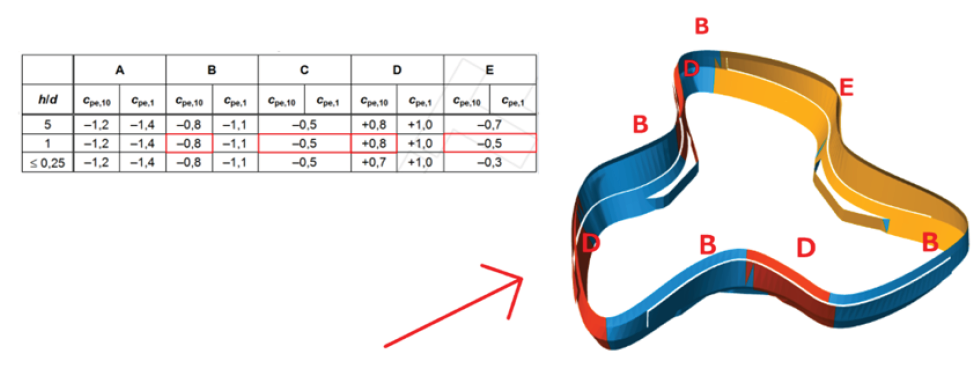

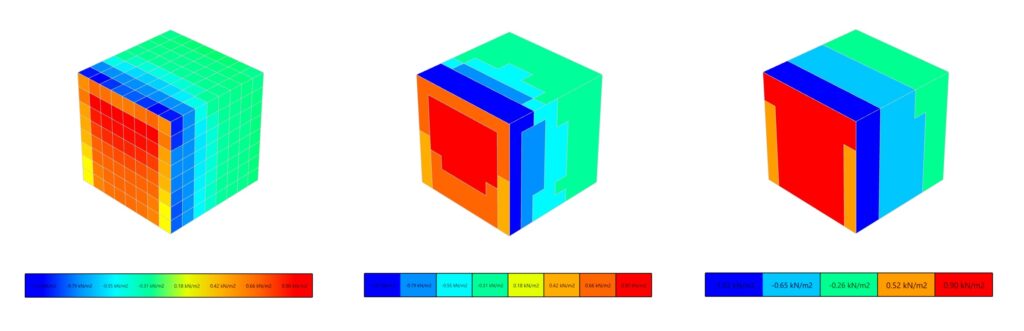

The effect of the wind acting on a structure can be calculated from the average wind speed and the fluctuating wind speed generated by the turbulence around the building. EN-1991-1-4 defines the wind-generated effects as simplified surface pressures for the calculation of wind loads acting on structures, considering the shape of the structure, its location, the roughness of the terrain, etc. Thus, the wind loads can be considered as a quasi-static external pressure equal to the effect of the turbulent wind with maximum speed. Then the effective surface pressure (or suction), can be determined as the result of the product of the peak pressure (at “z” height above the ground) and the pressure coefficients belonging to the building, according to the design codes, which are covering only a few regular shapers: flat roofs, different pitched roofs, vaulted roofs, domes, etc.

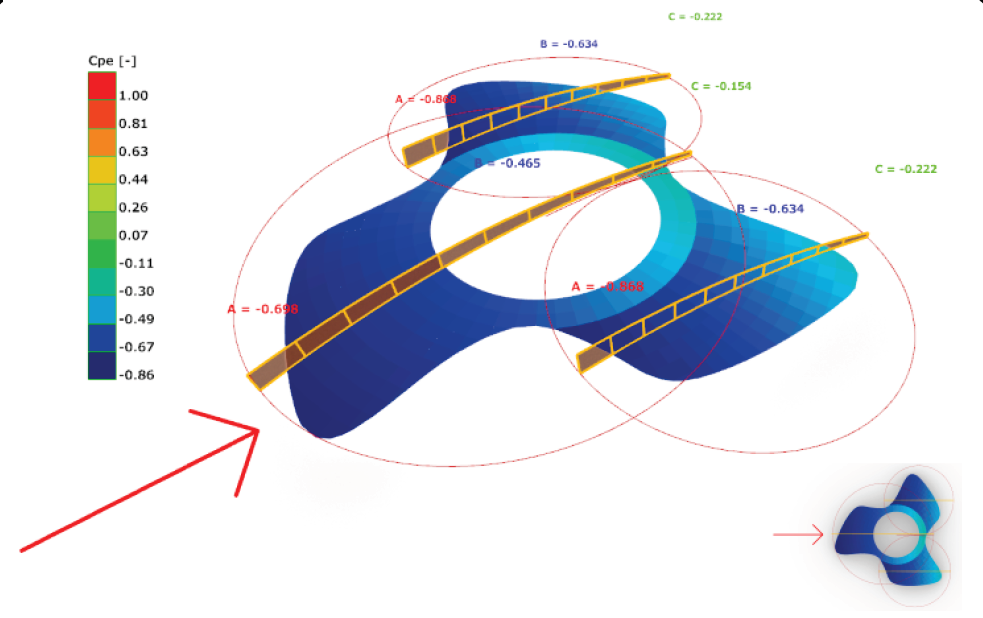

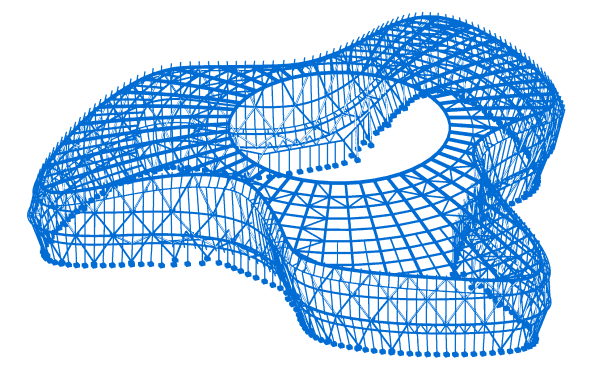

For instance, for the free-form structure below to determine these external pressure coefficients could be really challenging. First of all, due to the relatively low roof slope of the structure, it is difficult to decide whether to consider the roof as a flat roof with curved eaves or as a dome (due that it fits to the surface of a sphere). In the case of a dome, the standard gives 3 characteristic values in a relatively cumbersome way, depending on the eaves height, roof height and diameter of the building. Applying these values to the geometry is highly debatable, especially at the edges.

Similar questions are raised if we try to apply the pressure coefficients on walls which are not regular.

CFD Simulations

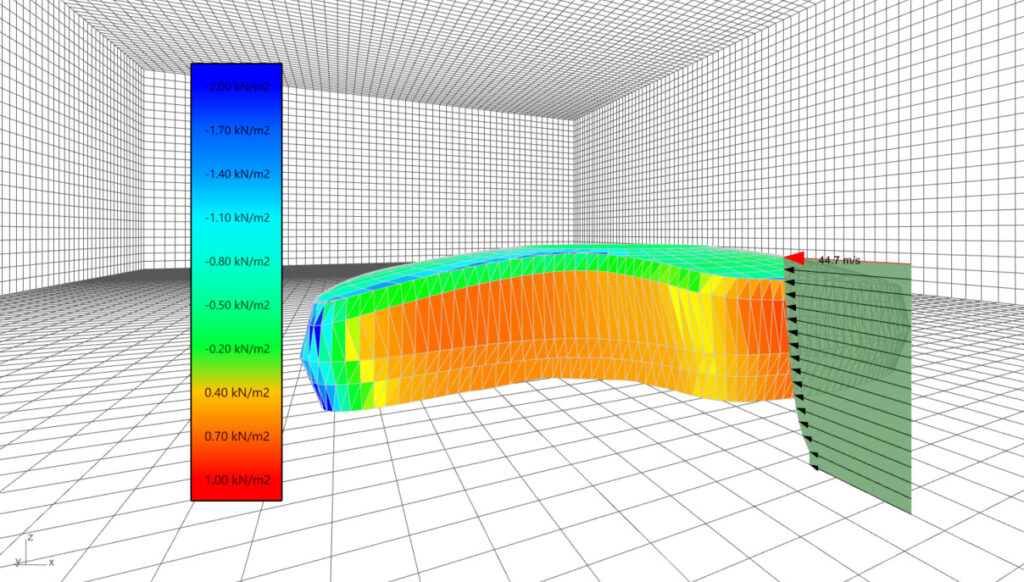

Computation Fluid Dynamics is a branch of fluid mechanics that deals with the numerical simulation and analysis of fluid flow and heat transfer phenomena. CFD involves using computer algorithms and numerical methods to solve the governing equations of fluid flow, such as the Navier-Stokes equations, on a discretized domain containing finite element volumes. For these problems OpenFOAM as a toolkit is one of the most suitable.

OpenFOAM contains several applications which can be divide to two main types. Solver-type applications are suitable for solving specific solid or liquid body mechanical problems, while the Utility-type can be used for mesh creation and data management.

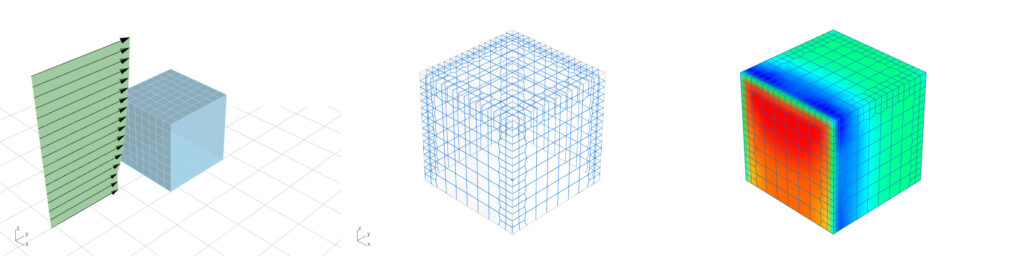

To prepare a CFD-based simulation, the following main steps can be identified:

- Preliminary mesh generation processes to create a model suitable both for simulation and load definition

- Define input parameters (wind speed, vp(z) corresponding to the peak value of the wind pressure,wind direction, roughness length z0, boundary conditions, etc.)

- OpenFOAM finite volume mesh generation (define refinements, castellated mesh and snap controls etc.)

- Turbulence model and solver definition (domain initial conditions, run controlling etc.)

The current stage of the development uses only one specific turbulence model, that handles the partial

differential equations of the kinetic energy and the energy distribution rate (k-ε model), with

the solver simpleFoam (SIMPLE = Semi – Implicit Method for Pressure Linked Equations) . In this

scenario, the simulation assumes the following conditions:

- Incompressible, rigid bodies

- Turbulent flow

- No physical time, quasi-static pressure

Our service as a general workflow for wind load evaluation

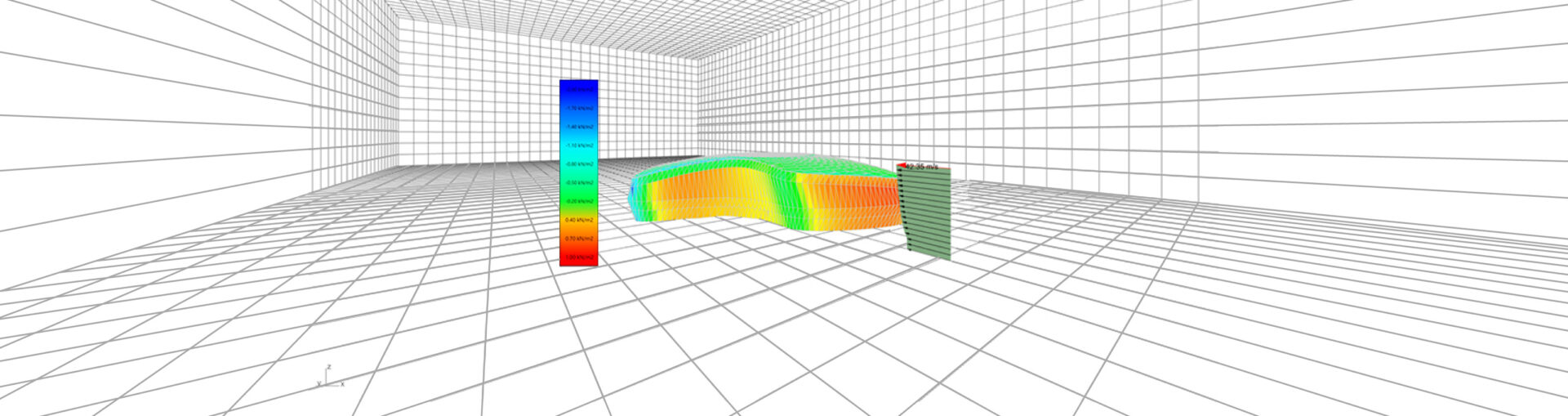

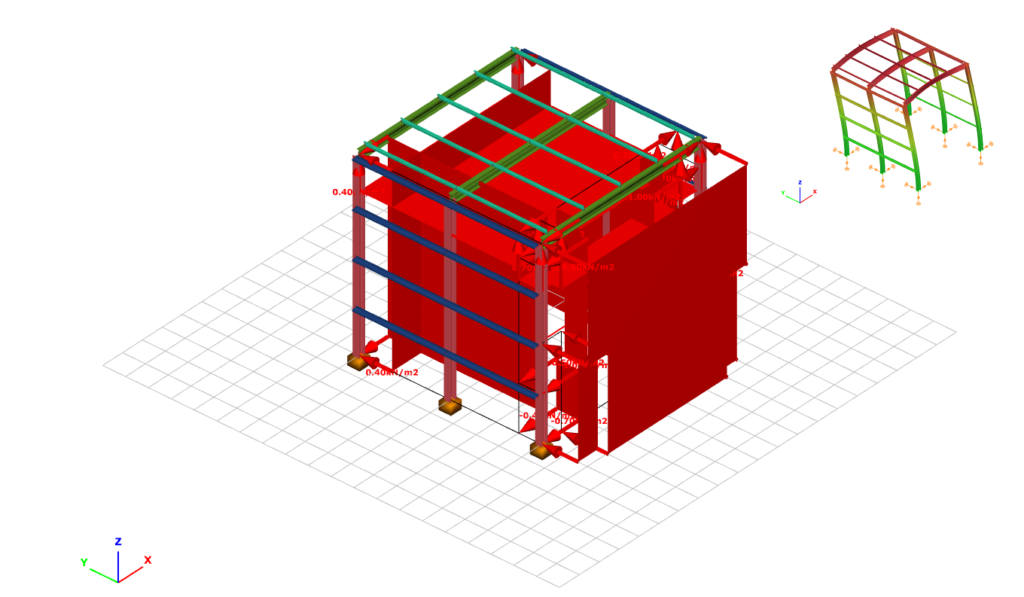

According to the steps we identified above we began the development of a service which as automatically as possible creates a premesh for load assignment and prepares the necessary data for OpenFOAM, which generates a finite volume mesh ( preprocess stage) and performs a simulation ( dataprocess stage) as shown below. For this, beyond the geometrical and meshing information, suchs as the cell size of the desired loads and the refinement, the user should provide only the wind reference base speed, the direction and the terrain category to define a wind profile according to the civil engineering logic (primarily the Eurocode wind profile corresponding to the peak velocity pressure).

The current development aimed an additional and in the same time the main feature ( postprocess stage) which offers an automated conversion from the resulted pressure values to usable surface loads according to the users preferences. It will be possible to directly assign the simulation results to the premesh, or to apply a zoning logic, similar to the standard.

In conclusion, a serious potential can be observed in the feature, mainly due to its versatility. However, experience shows that although CFD can be used to perform wind load simulations for industrial use, its pertinence is highly dependent on the quality of the input parameters. So a minimal fluid dynamic expertise is still required, but the current state of the development already offers a solution for the structural engineers, in order to create these simulation relatively easily. The service is planned to be implemented in multiple channels using our existing platforms: Consteel (direct desktop use on Consteel models), Steelspace (cloud based use on compatible models) and Grasshopper (use on any models defined in the GH environment for instance with Pangolin) to make it available for as many engineers using different tools as possible.