Discover an in-depth case study detailing the expansion of a Turda, Romania plasterboard factory, which shows how the expansion led to the construction of nine new structures. This project, which uses a central parametric model, won third place in this year’s The Steel Lion Award 2023 competiton, thanks to its innovative use of Consteel software for steel structural design and Pangolin, the Rhino-Grasshopper plugin for Consteel.

1. Project Info

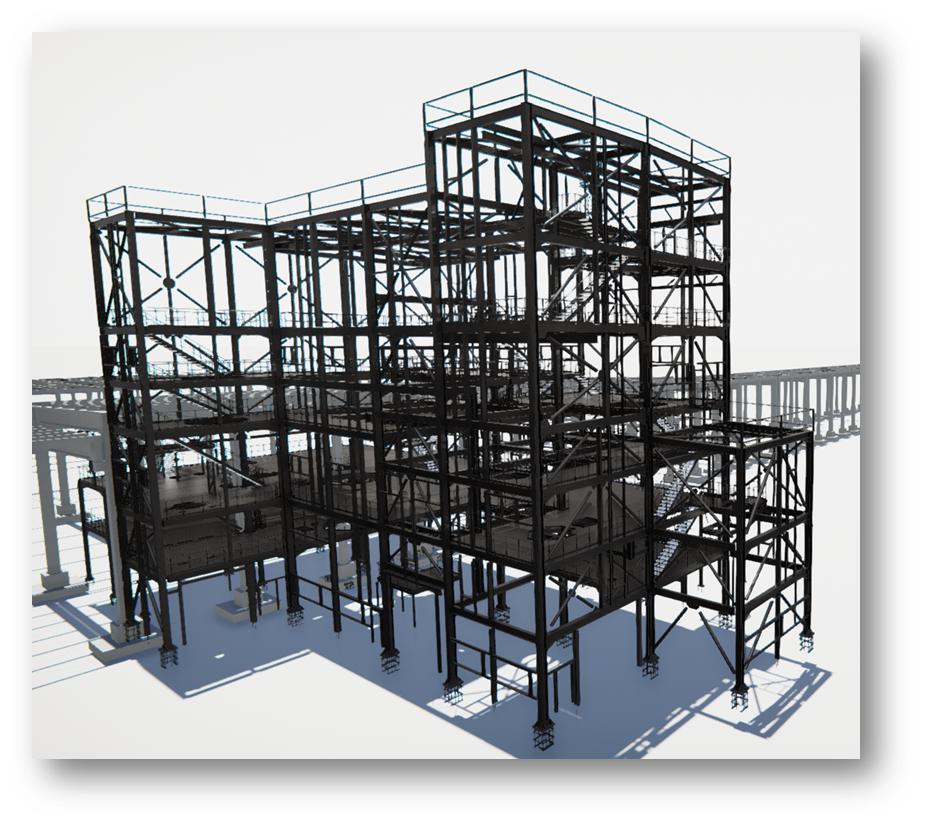

The aim of the project is to expand an existing plasterboard factory in Turda, Romania, resulting in the creation of 9 new structures.

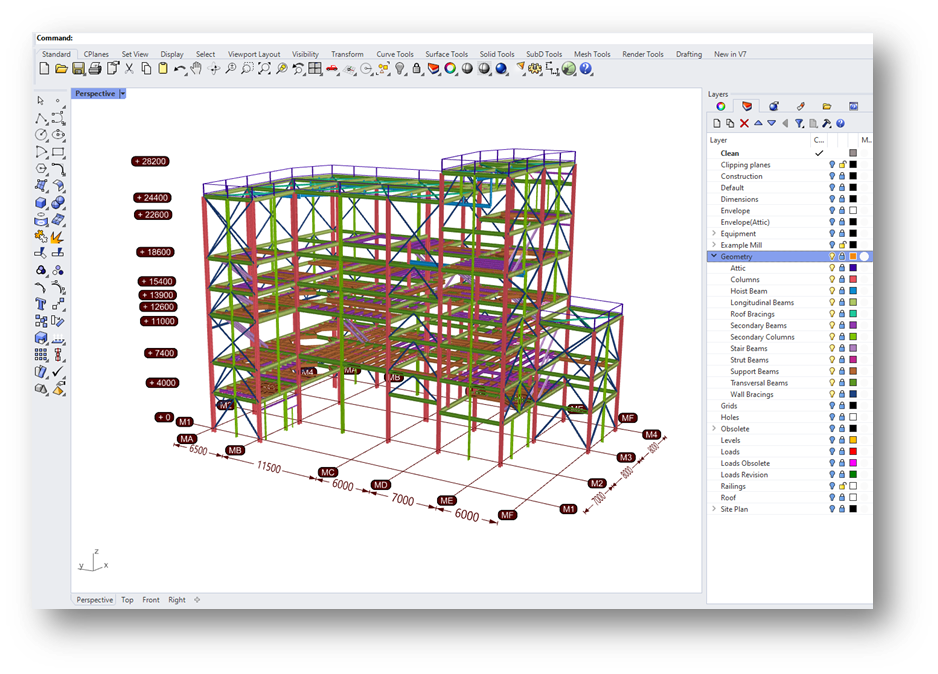

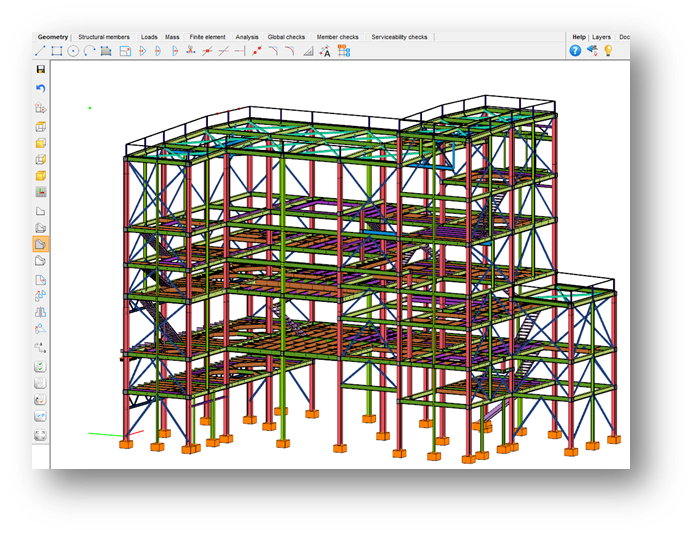

These buildings serve various purposes, from raw material processing to waste storage. The building that monitors and serves the manufacturing process is called the “mill,” constructed from a multi-storey rigid steel frame structure. The maximum frame span is 8 meters, and the total height of the 7-story structure is 28 meters.

2. Central parametric model

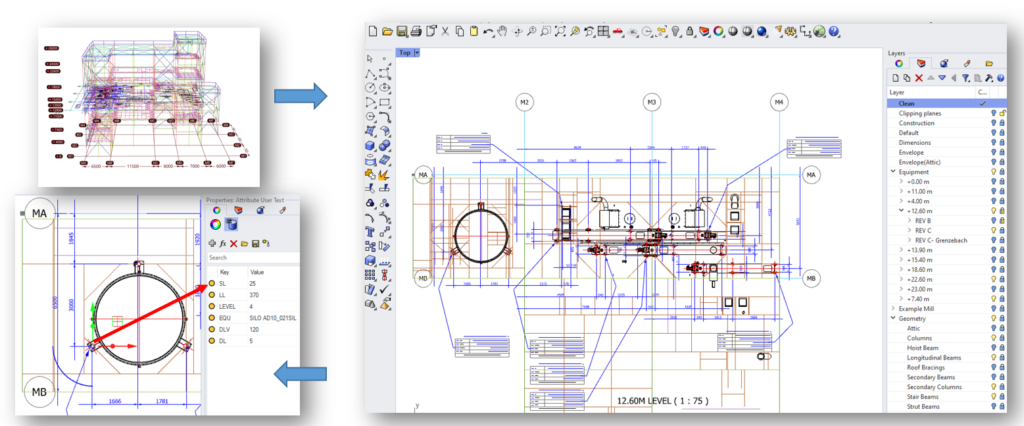

While the geometry of the structure is based on classic shapes that may not necessarily require parametric design methods, our goal was to parameterize and create a central BIM model to keep all data in one place during the project’s design process. This data includes 3D models of the technological equipment, technical data sheets, and plans related to them, along with permanent and live loads, all revisions, architectural plans, and more. Given the data provided, we constructed the geometry, defined the loads, and other relevant information. The resulting structure was a complete wireframe model, and its global static analysis was performed using Consteel.

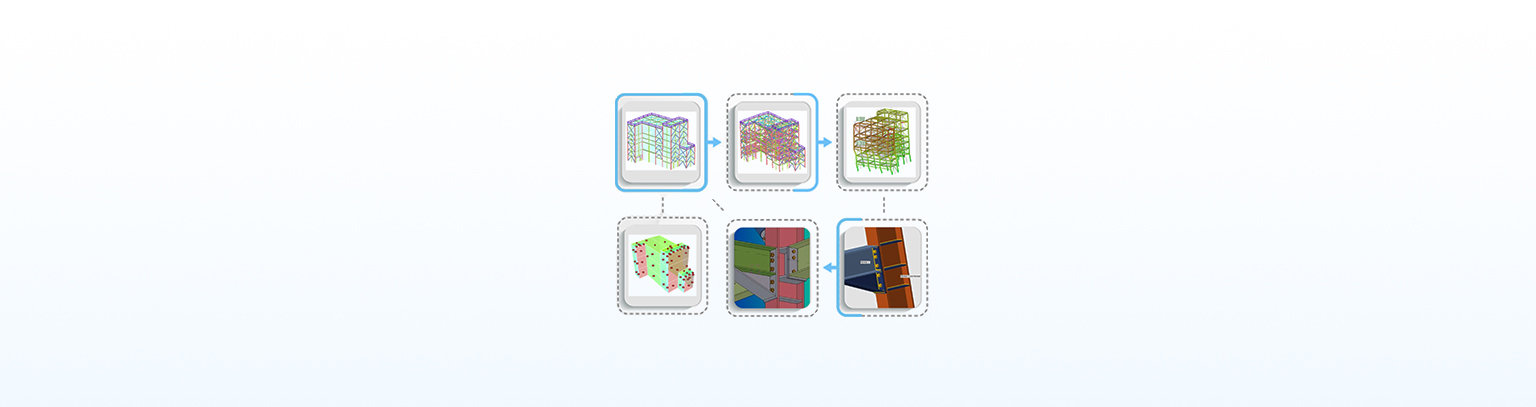

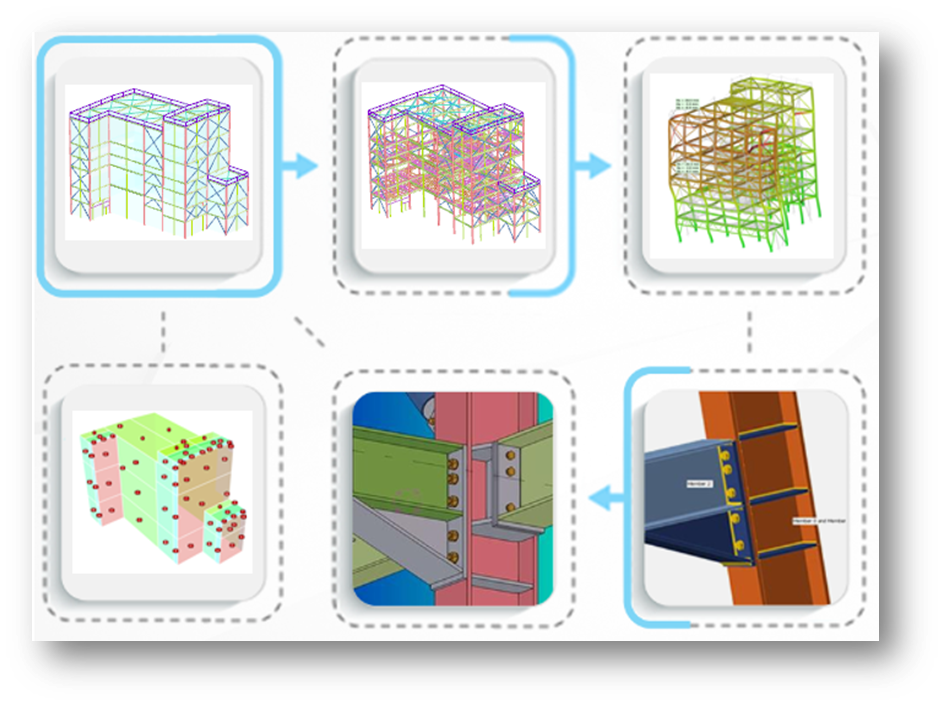

In this way, the centralized model controlled the entire design process from Rhino-Grasshopper interfaces (top-left corner). From here, the complete load evaluation process was coordinated (bottom-left), the construction of the structural model (top-center), the generation of models required for joint calculations (bottom-right) based on the results of the structural analysis (top-right), and ultimately, the whole detail design (bottom-center).

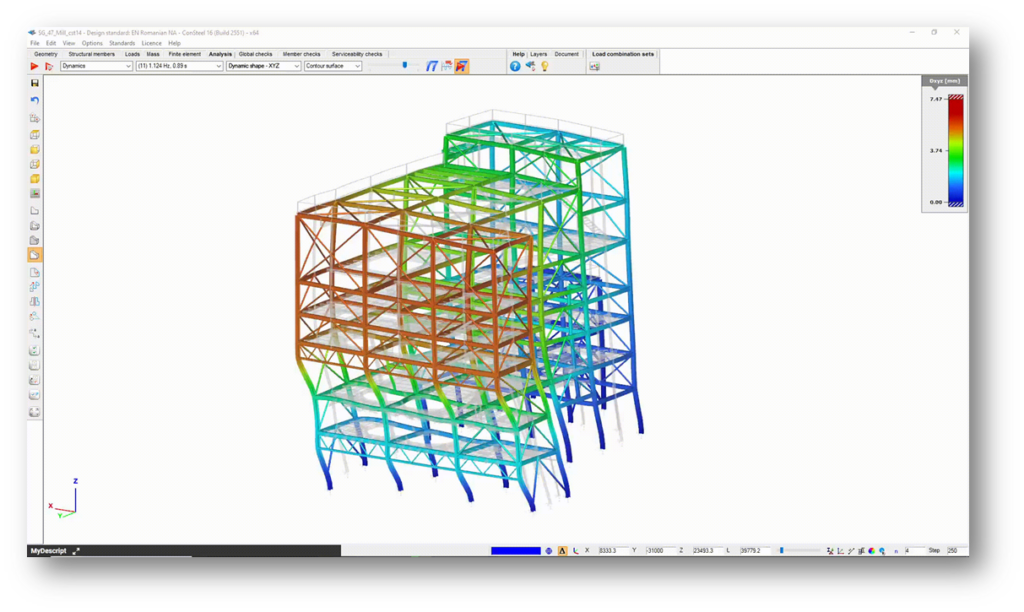

3. Analysis in Consteel

The primary challenge in the design was harmonizing the technology with the structure. Essentially, the design of the technological equipment occurred in parallel with the design of the structure, and the structure had a subordinate role throughout the whole process, necessitating flexibility to adapt to any modifications from the technology side. Within Consteel, we continuously optimized the structure, and utilizing Pangolin’s bidirectional functionality it allowed us to update our centralized model almost instantly. This ensured that the current state was always available, enabling concurrent detailing of the building. Another challenge was that the building was connected to a precast concrete production building. For the affected facades, the ordinary bracing system couldn’t be applied on the first three levels, significantly affecting the structure’s global behavior under horizontal loads. Therefore, it was crucial to consider all structural elements within a global model, in this case, together with the trusses providing the necessary horizontal rigidity.

4. Joint Filtering

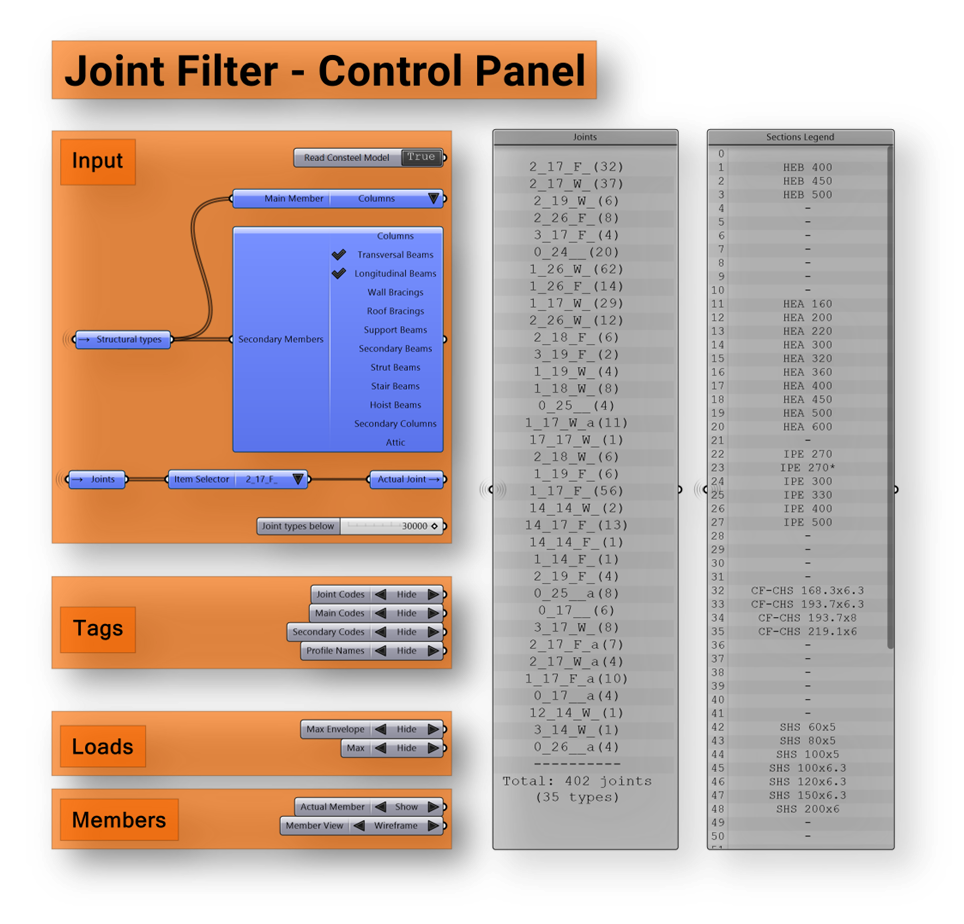

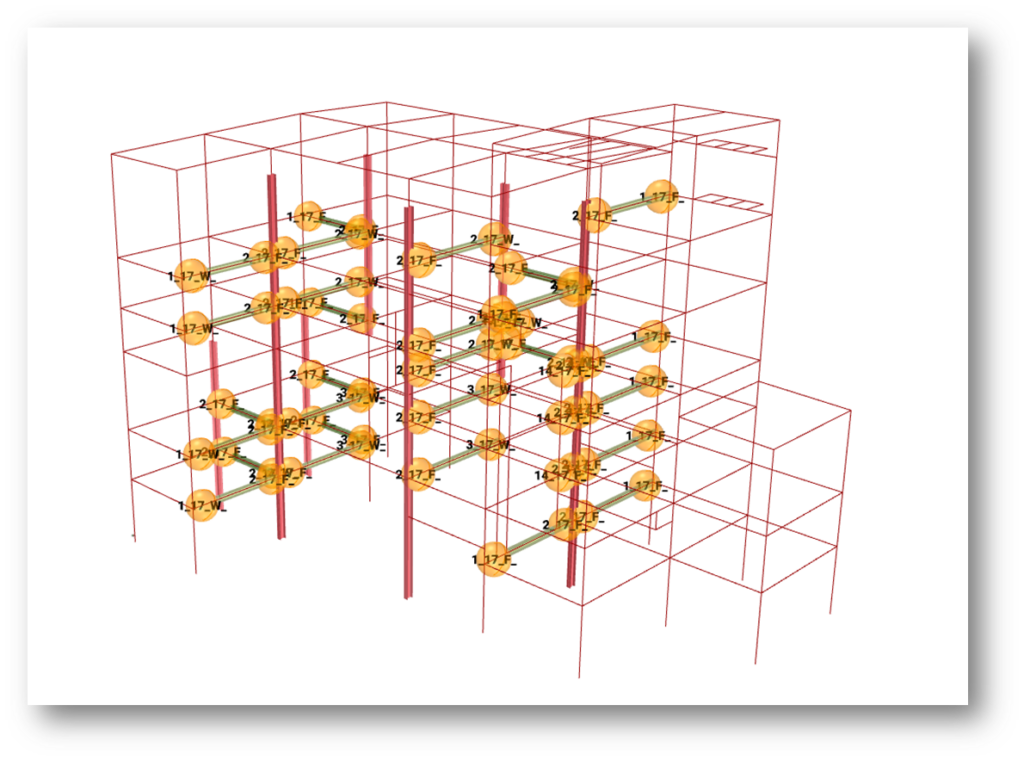

Following the main structural analysis, we performed joint analysis using the Grasshopper-IdeaStatica compatibility. This allowed us to filter out type joints (e.g., column bases, column-to-beam connections) from the Consteel model, which were then dimensioned for the internal forces collected automatically. These forces, while considering all possible positions for the selected type joints, represented the maximum concurrent and the absolute maximum values. Using predefined Tekla macros, we distributed the dimensioned connections to all positions with the help of Grasshopper. This method enabled the scattering of 2074 joints on the strut beams with a single click. Using this approach, we distributed over 3800 Tekla macros under Grasshopper control.

5. Conclusions

The design process consisted of two main phases. During the conceptual design phase, which served as the basis for the final authorization plans, we began writing scripts based on a parametric central model. We handled this as an internal development, which could also serve as a starting point for similar projects in the future. Thus, by the time we were creating final detailed plans in the second phase, we had a highly flexible tool at our disposal, providing data for structural checks, global and joint dimensioning, detailing, and ultimately for drawings. This workflow proved to be extremely efficient, requiring only one project lead structural engineer and one engineer responsible for script development and usage throughout the roughly two-year design process from the steel structure perspective. Therefore, when everything was considered final, we were able to involve an additional five engineers, and together, we completed the joint dimensioning, the remaining manual detailing, and the manufacturing design in approximately two months.