Welded tapered portal frames

Portal frames may be one of the most commonly used structural types in steel halls, but that doesn’t mean designing them is always straightforward. Striving for optimal cross-sections, engineers often turn to welded, tapered members, but they frequently face the challenge of designing these efficiently while navigating vague or insufficient guidance from standards. The complexity arises from the unique behavior of such frames, typically involving Class 4 cross-sections, irregular support conditions, and moment-resisting frame corners, all of which together pose significant challenges in both analysis and design.

No credit card required

Specific Feature Solutions for welded tapered portal frames in Consteel

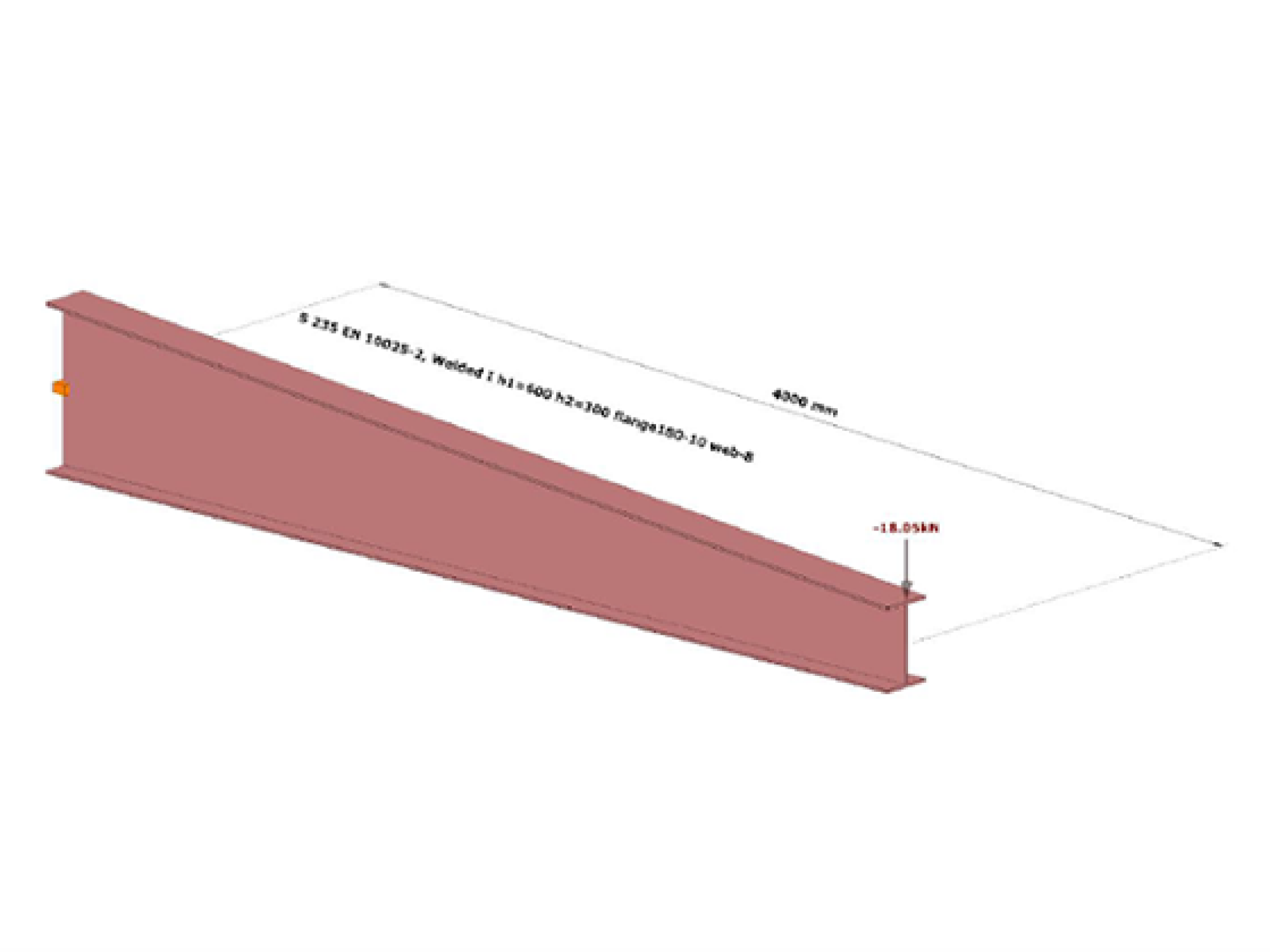

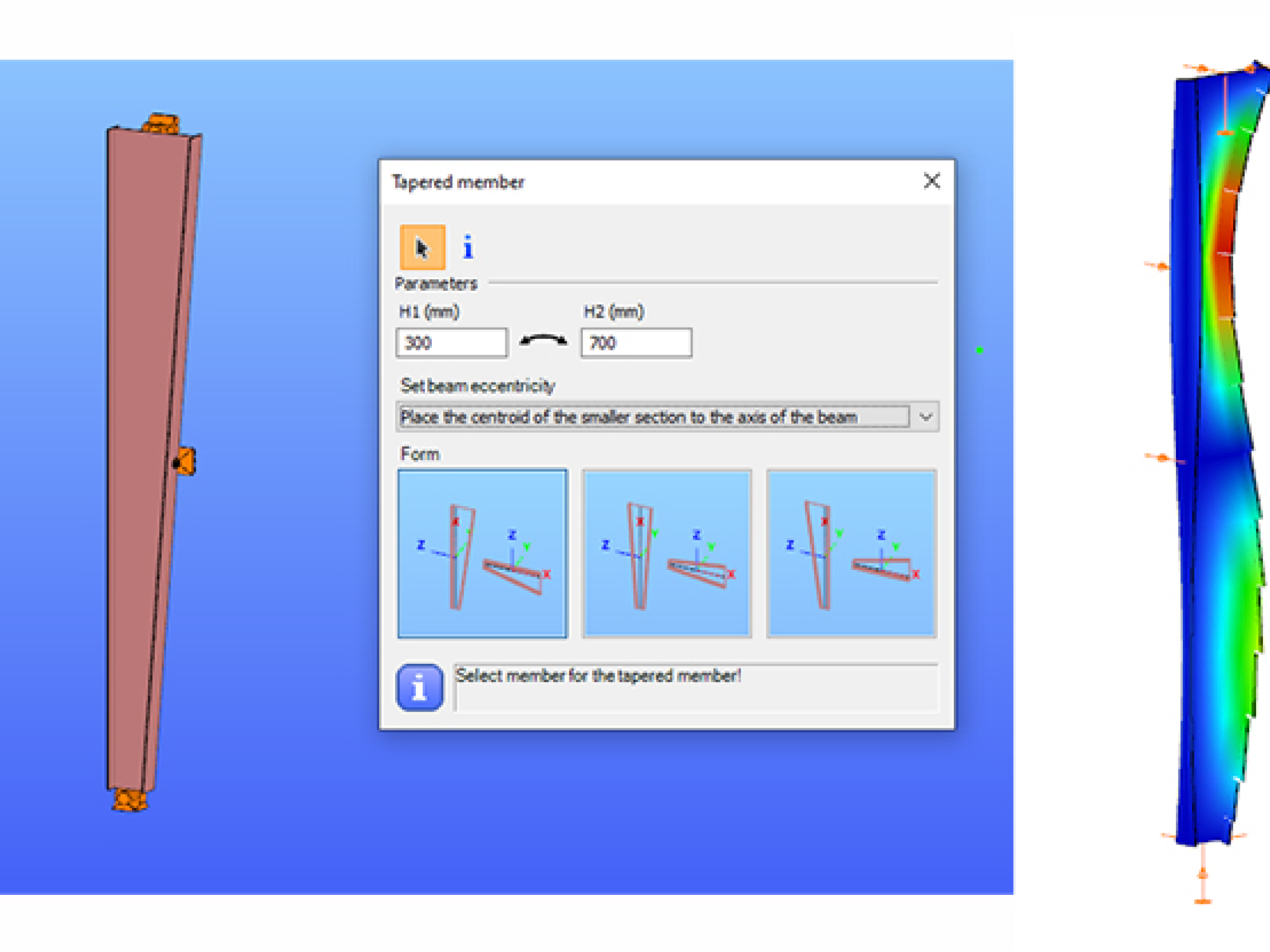

Easy modeling of nonunifrom members – Tapered members

In Consteel, the tapered members are easy to define with just a few clicks and with the help of realistic visulalisation, despite of the numerous options provided for geometry. Member eccentricities due to placement options are recognized and considered automatically during analysis, as well as the special calculation method serving the correct transfer of warping between the finite elements of different heights.

Easy modeling of plated girders – Superbeam

Considering shear and rotational restraints provided by the various types of sheeting is unavoidable during cold-formed purlin design. In Consteel, the definition of these restraints is practical for everyday use and supplemented with an automatically applied special purlin design mode of analysis and design calculations. As purlins can be modelled as integrated parts of the structural model, their restraining effect to the main structure can also be considered.

Exact analysis of continuous frame corner regions

Corner zones have usually significantly different behavior than the connected beam members. Since these zones are very short, the behavior is influenced dominantly by the shear effect. Frame corner regions are semi-automatically recognised in Consteel and specific methods are applied to them during analyis and design with the consideration of kinematic constraint elements between the 7. DOF displacements of the neighbouring members (warping transfer) according to the chosen frame corner topology.

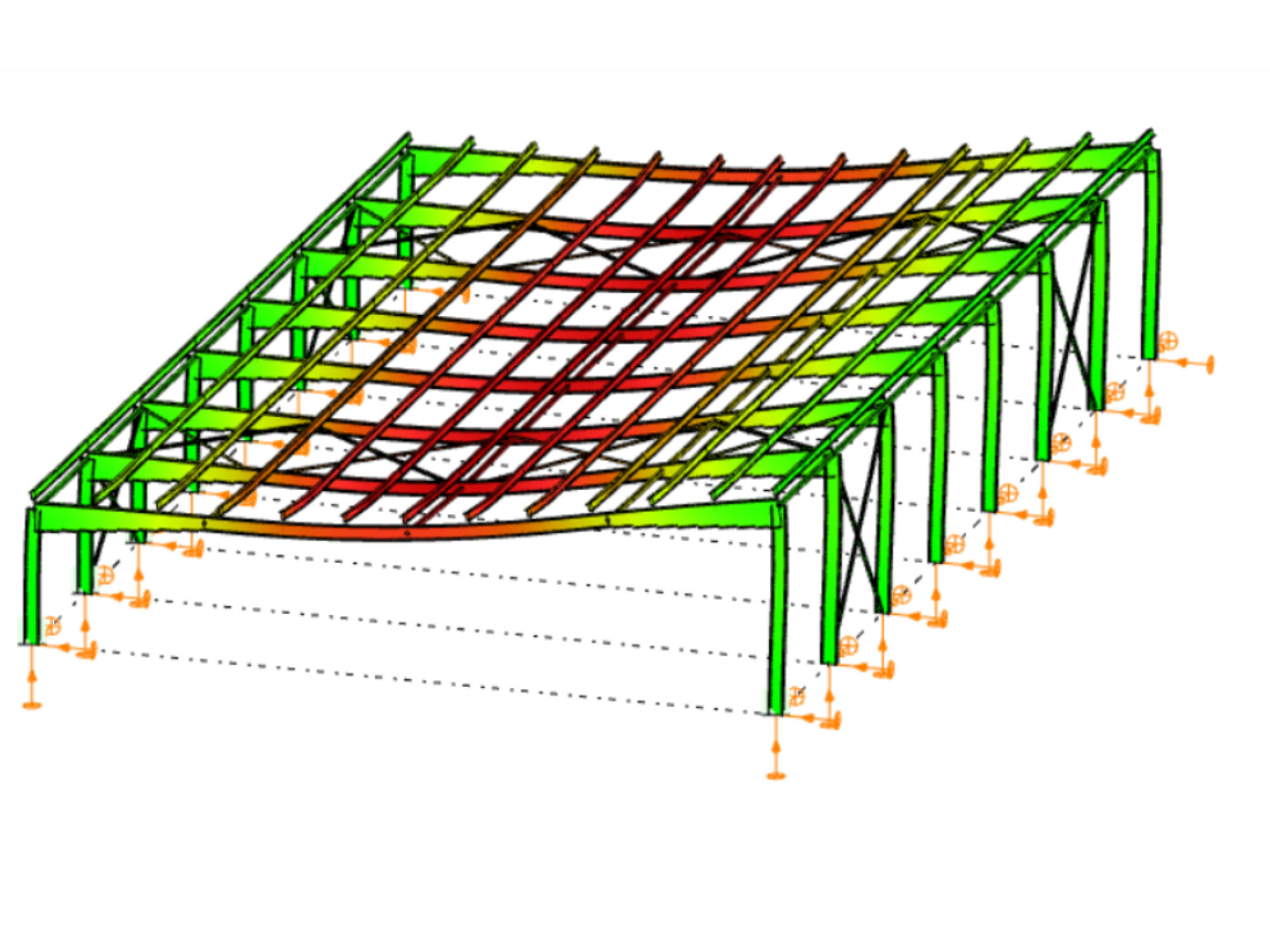

Immersive visualization of the true structural behavior

The key uniqueness of Consteel lies in its ability to model real structural behavior as accurately as possible, building automation and unique design procedures upon this foundation.

A crucial element of this approach is the immersive visualization, which enables a realistic representation of the deformations associated with the actual structural behavior—whether they result from applied loads or buckling shapes.

This visualization goes beyond conventional displacement components by also incorporating warping and other local deformations of structural elements, making the representation smoother and more realistic. It almost depicts the structure as if the beams and plates were analyzed using shell models.

Why is this important?

Because a visually striking and intuitive representation conveys the structural behavior far more effectively than even multiple pages of calculations or tables.

Automatic buckling design based on the ‘General Method’

General Method is the smartest way of stability design, described in EN 1993-1-1. It is applicable for any complex cases of out-of-plane buckling problems (flexural, torsional, and lateral-torsional buckling, and any interactions of these) with arbitrary members, loading and support conditions. Based on the global buckling and sensitivity analysis, it provides a comprehensive and automatic solution for stability design.

OUR PARTNERS

WHY CHOOSE CONSTEEL?

WHO RECOMMENDS US?

‘Consteel is a great asset for Arambol Ingeniería S.L. Thanks to its workflow we can design, calculate and present a project in record time. The program is very intuitive and easy to use. Technically, the seventh degree of freedom is an enormously useful tool to check structures with the general method, and even obtain reliable results thanks to the use of buckling shapes together with the imperfections to obtain utilization ratios that, physically, are more realistic than the reduction coefficients. Consteel has very specialized features such as the shear field or the frame corner wizard that add an extra degree of professionalism to the calculation, which translates into greater efficiency in the use of steel and, therefore, money.’

‘The Alba Arena project highlighted the extraordinary potential of the Consteel software and Pangolin. It is a pioneering technology that enables the parametric design of complex geometry and large-scale structures through the Grasshopper system. The Pangolin award is an exceptional recognition for me and the bim.GROUP, as it is a positive feedback on the quality of our work and an opportunity to showcase our expertise on an international level.’ said Dávid Lewandowski, Steel Structure Designer, regarding the award.’

‘Consteel’s technical support team is very professional. Especially Mr. Balint Vaszilievits-Sömjén, he has been a great help to us! We were impressed by his professionalism and dedication. We are satisfied with the use of Consteel, which has proven its worth in our international projects.’

‘I started using the Consteel design software during my university studies, when it was Consteel version 6. Even then I was impressed by the simplicity, transparency, and speed of the program. Since then, I have had the pleasure of designing many structures with the program, from small to large: industrial halls, office buildings, large opening roof structures, staircases, flying garages, pipe bridges, canopies, secondary closure elements, or the transmission line poles on which my doctoral thesis was based.

The bottom line is that it allows a structural engineer to model any structure in 3D in a structurally correct way, yet quickly and with a low risk of error. The most complex geometric type includes, for example, a lattice structure, where stability loss shapes can be efficiently calculated and sections optimised. One of my favourite features is the interpretability of the results, and the fact that the program receives significant updates year after year, which is the most user-oriented.’

‘From the very beginning, I really like Consteel because it can be used to perform global steel structure tests in a complex and compact way, efficiently. In addition, the software integrates well with automated parameter-driven design algorithms – so I can heartily recommend it.’

The approach of the Consteel team to software development also deserves praise, which shows a well-thought-out path of software development in terms of suitability for practical applications (and not only in terms of changing the graphic interface as is the case in other developers).

We recommend Consteel to all experienced engineers.’

knowledge behind consteel

Example ModelS

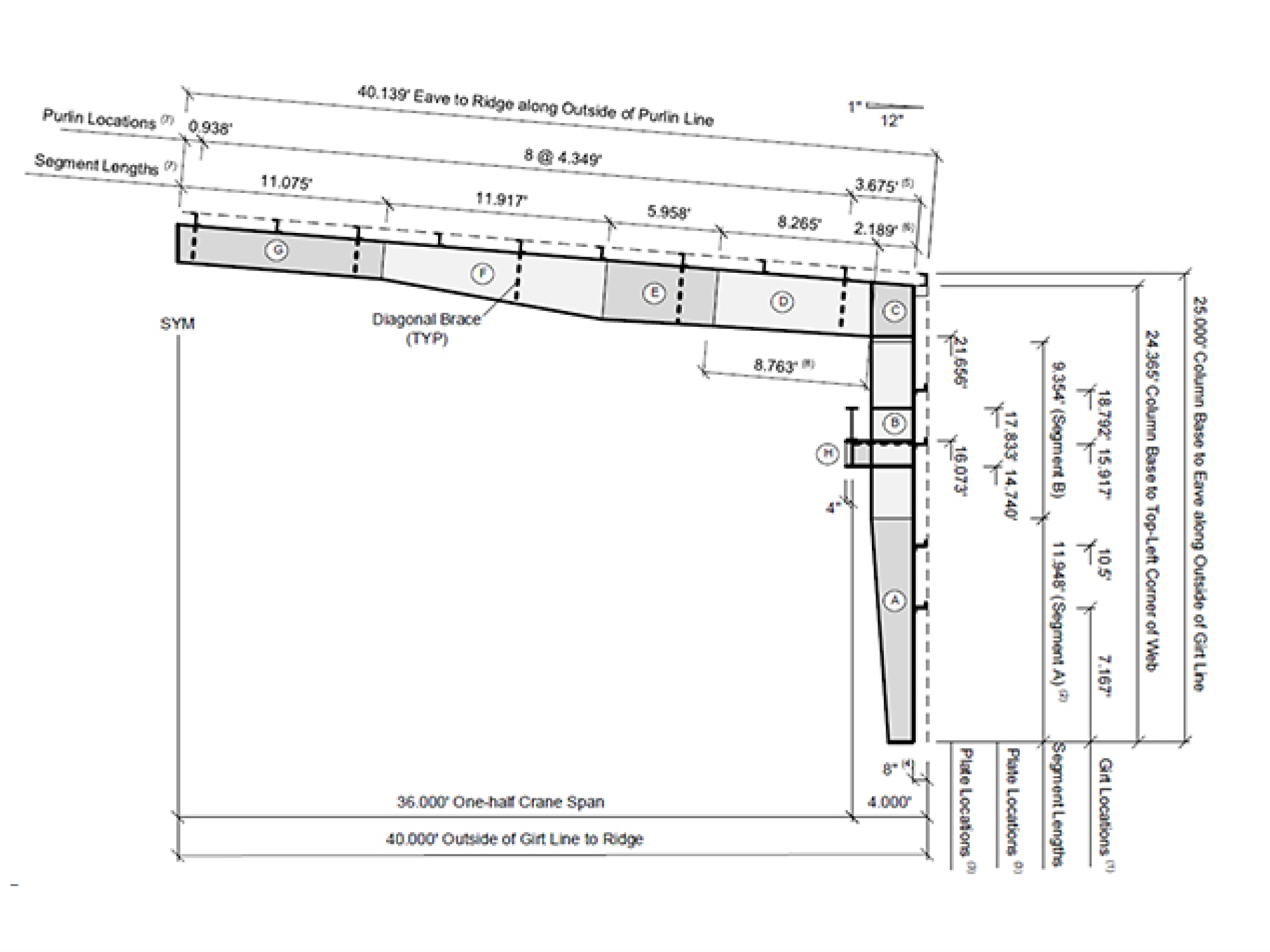

Design a pre-engineered Metal Building

Did you know that you can use Consteel to design a pre-engineered Metal Building with all its unique characteristics, including web-tapered welded members, the interaction of primary and secondary structural elements, flange braces, shear and rotational stabilization effect provided by wall and roof sheeting?

Download the example model and try it!

SIMPLIFY YOUR DESIGN PROCESS