Knauf Insulation Factory in Târnăveni

Structural Engineering

Tünde András, Noémi Egyed, Ioana Secheli, Attila Feleki, Károly Szakács, Gergő Szabó

design office

Location

Romania

Built in

2024

The area of the building

3850 m2

challenges behind the project

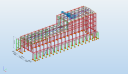

The presented structure is part of a multi-building project that will serve as the new Knauf Insulation factory in Dicsőszentmárton.

It is configured as a single storey frame structure, with 6 m distance between axes in longitudinal direction. The frame configuration is a truss solution, the column has a 1.4 m distance between its flanges, and truss-girder has a 24.5 m opening with variable height between 1.70 m and 2.95 m. There is a height change in the middle of the building which is also the boundary of two separate production processes. The higher melter section is 36.3m high while the lower fibreizer section is 24.3 m high. The area of the building is 3850 m2, and the total used steel quantity is 830 tones.

The cladding of the building was made of sandwich panel on the walls , and trapezoidal sheeting with PVC membrane on the roof. At specific locations blast relief panels were used, which needed a distinct fastening design. This design was carried out in a way to withstand the wind load requirements, but also allow the panel to be blown away from the possible explosion.

The biggest challenge was the anchoring of columns to the foundations, which was caused by the truss configuration of the columns. At the location of windbracings, normal forces up to 3.5-4 MN appeared at the bottom of the columns. The windbracings were designed as composed profiles.

There are 1-1 annex buildings along each side of the structure, one with 10 m high and 4.25 m opening and the other with 8.65 m opening 17.2 m high. Also, at the melter area of the structure, an anex structure with a piperack is located on the roof. Due to the substantial height of the building, numerous calculations were carried out on the construction stage, to determine the cladding sequence.

WHO RECOMMENDS US?

‘Consteel is a great asset for Arambol Ingeniería S.L. Thanks to its workflow we can design, calculate and present a project in record time. The program is very intuitive and easy to use. Technically, the seventh degree of freedom is an enormously useful tool to check structures with the general method, and even obtain reliable results thanks to the use of buckling shapes together with the imperfections to obtain utilization ratios that, physically, are more realistic than the reduction coefficients. Consteel has very specialized features such as the shear field or the frame corner wizard that add an extra degree of professionalism to the calculation, which translates into greater efficiency in the use of steel and, therefore, money.’

‘The Alba Arena project highlighted the extraordinary potential of the Consteel software and Pangolin. It is a pioneering technology that enables the parametric design of complex geometry and large-scale structures through the Grasshopper system. The Pangolin award is an exceptional recognition for me and the bim.GROUP, as it is a positive feedback on the quality of our work and an opportunity to showcase our expertise on an international level.’ said Dávid Lewandowski, Steel Structure Designer, regarding the award.’

‘Consteel’s technical support team is very professional. Especially Mr. Balint Vaszilievits-Sömjén, he has been a great help to us! We were impressed by his professionalism and dedication. We are satisfied with the use of Consteel, which has proven its worth in our international projects.’

‘I started using the Consteel design software during my university studies, when it was Consteel version 6. Even then I was impressed by the simplicity, transparency, and speed of the program. Since then, I have had the pleasure of designing many structures with the program, from small to large: industrial halls, office buildings, large opening roof structures, staircases, flying garages, pipe bridges, canopies, secondary closure elements, or the transmission line poles on which my doctoral thesis was based.

The bottom line is that it allows a structural engineer to model any structure in 3D in a structurally correct way, yet quickly and with a low risk of error. The most complex geometric type includes, for example, a lattice structure, where stability loss shapes can be efficiently calculated and sections optimised. One of my favourite features is the interpretability of the results, and the fact that the program receives significant updates year after year, which is the most user-oriented.’

‘From the very beginning, I really like Consteel because it can be used to perform global steel structure tests in a complex and compact way, efficiently. In addition, the software integrates well with automated parameter-driven design algorithms – so I can heartily recommend it.’

The approach of the Consteel team to software development also deserves praise, which shows a well-thought-out path of software development in terms of suitability for practical applications (and not only in terms of changing the graphic interface as is the case in other developers).

We recommend Consteel to all experienced engineers.’

SIMPLIFY YOUR DESIGN PROCESS